In completion of oil and gas wells, cement separates the wellbore, prevents casing failure, and keeps wellbore fluids from contaminating freshwaters. The basic factors engineers and operators must consider for successful cementing jobs are summarized in seven basic ideas:

- Condition the Drilling Fluid

- Use Centralizers

- Move the Pipe

- Increase the Displacement Rate

- Design Slurries for Proper Temperature

- Select and Test Cement Components

- Select a Proper Cementing System

1. Condition the Drilling Fluid

The drilling fluid condition is the most important variable in achieving very good displacement during a cementing job. As the workers pull the drill pipe, run the casing, and prepare for cementing operations, the drilling fluid in the wellbore basically remains static and hardens. Pockets of mud commonly exist after a wellbore is drilled and they make displacement difficult. These pockets of gelled fluid must be broken up. Regaining and maintaining good fluid mobility after running the casing is essential.

2. Use Centralizers

Centralizers are effective mud displacement helpers. Centralizers make easier the removal of gelled-mud and allow better cement bond with the wellbore. Centralizers are designed to serve various needs, for instance, they help with well control, provide increased mud-removal benefits, optimize drilling-fluid displacement. When a casing is poorly centralized the cement bypasses drilling fluid by following the path of least resistance. Good pipe standoff helps ensure uniform flow patterns around the casing. Centralizers also change fluid flow patterns and promote better mud displacement and removal.

3. Move the Pipe

Moving the casing before and during cementing breaks up the gelled pockets and it loosens the cuttings trapped in the gelled mud. Pipe movement allows high displacement efficiency at lower pump rates by keeping the drilling fluid flowing.

Movement compensates partially for poorly centralized casing by changing the flow path and allowing the slurries to circulate completely around the pipe. In some instances, some liner hangers and mechanical devices prevent casing movement, which must be considered during the cement displacement design.

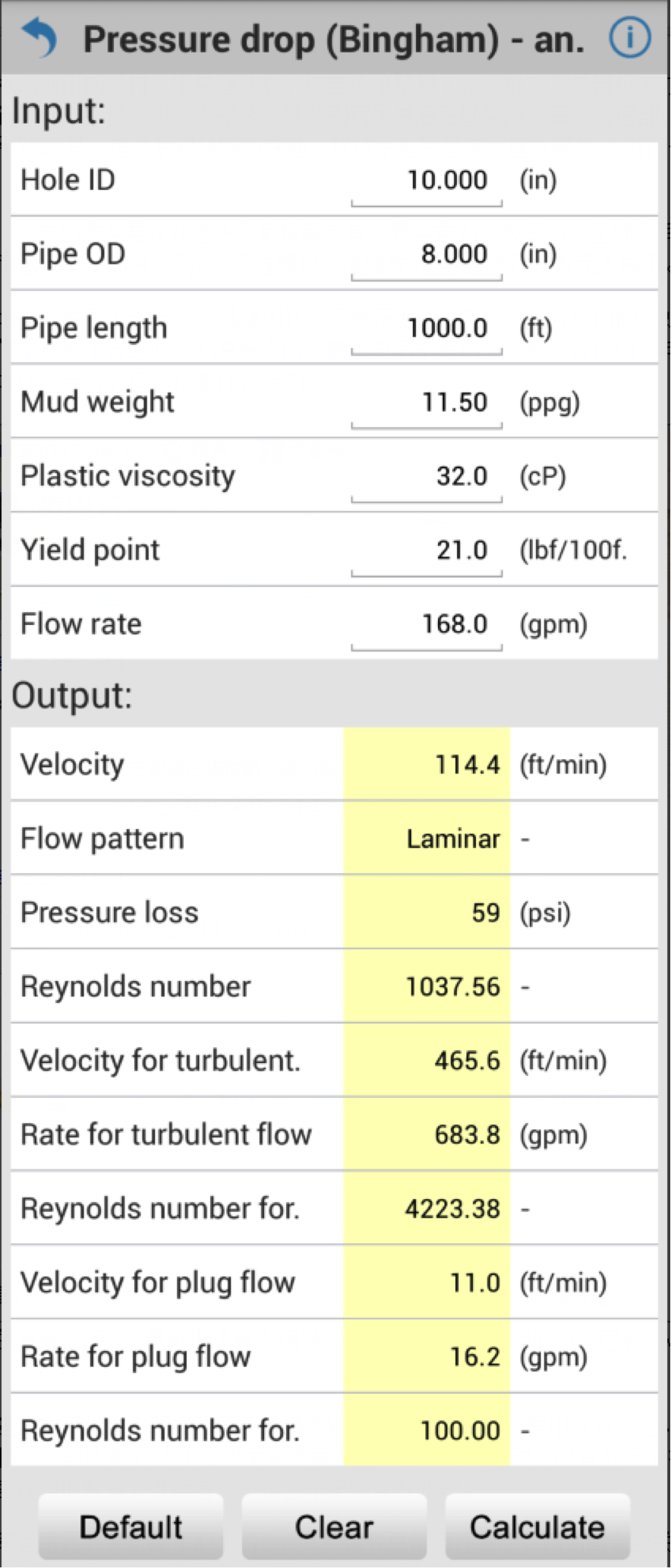

4. Increase the Displacement Rate

High-energy flow in the annulus is more effective in ensuring good mud displacement. Turbulent flow around the casing circumference is desirable, but not necessarily essential. The best cementing results are obtained when the spacers and cement are pumped at maximum energy, the spacer is appropriately designed to remove the mud, and a more proficient cement is used.

5. Design Slurries for Proper temperature

Operators can optimize the slurry design if they know the actual temperature the cement will encounter. Bottomhole cementing temperatures affect the slurry thickening time, set time, rheology and the compressive-strength development. Operators tend to overestimate the amount of materials required to keep cement in a flowing for pumping, which can result in unnecessary cost and well-control problems. They can optimize cost and displacement efficiency by designing the job on the basis of actual wellbore circulating temperatures, obtained from a downhole temperature sub recorder.

6. Select and Test Cement components

Operators are encouraged to design cement slurries for specific applications, with good properties to allow placement in a normal period of time. The ideal cement slurries have no measurable free water, provide adequate fluid-loss control, have adequate retarder to ensure proper placement, and maintain a stable density to ensure hydrostatic control.

Before performing the job, they should check the cement reaction and actual location mix water to ensure that the formulation will perform as it is expected. Contaminants in the mix water can produce large variances in thickening time and compressive strength.

Organic materials and dissolved salts in mix water can affect the slurries setting time.

Cement dehydration from the loss of filtrate to permeable formations can cause bridging and increased friction pressure, viscosity, and density. Pump pressures can increase and additives can be used to provide fluid-loss control when is necessary to compensate for dehydration.

7. Select a Proper Cementing System

Operators select cement systems based on job objectives and well requirements.

Cement is basically inflexible. Cementing systems are similar in many ways, but sometimes they vary, for instance, in their capability to provide good zone isolation in changing environments. The cement selection has always been on the basis that higher compressive strengths result in higher cement sheath quality. Research has proven that the ability of cement to provide good zonal isolation is better defined by other mechanical properties. Good isolation does not necessarily require high compressive strength. The real competence test is whether the cement system in place can provide zone isolation for the life of the well.

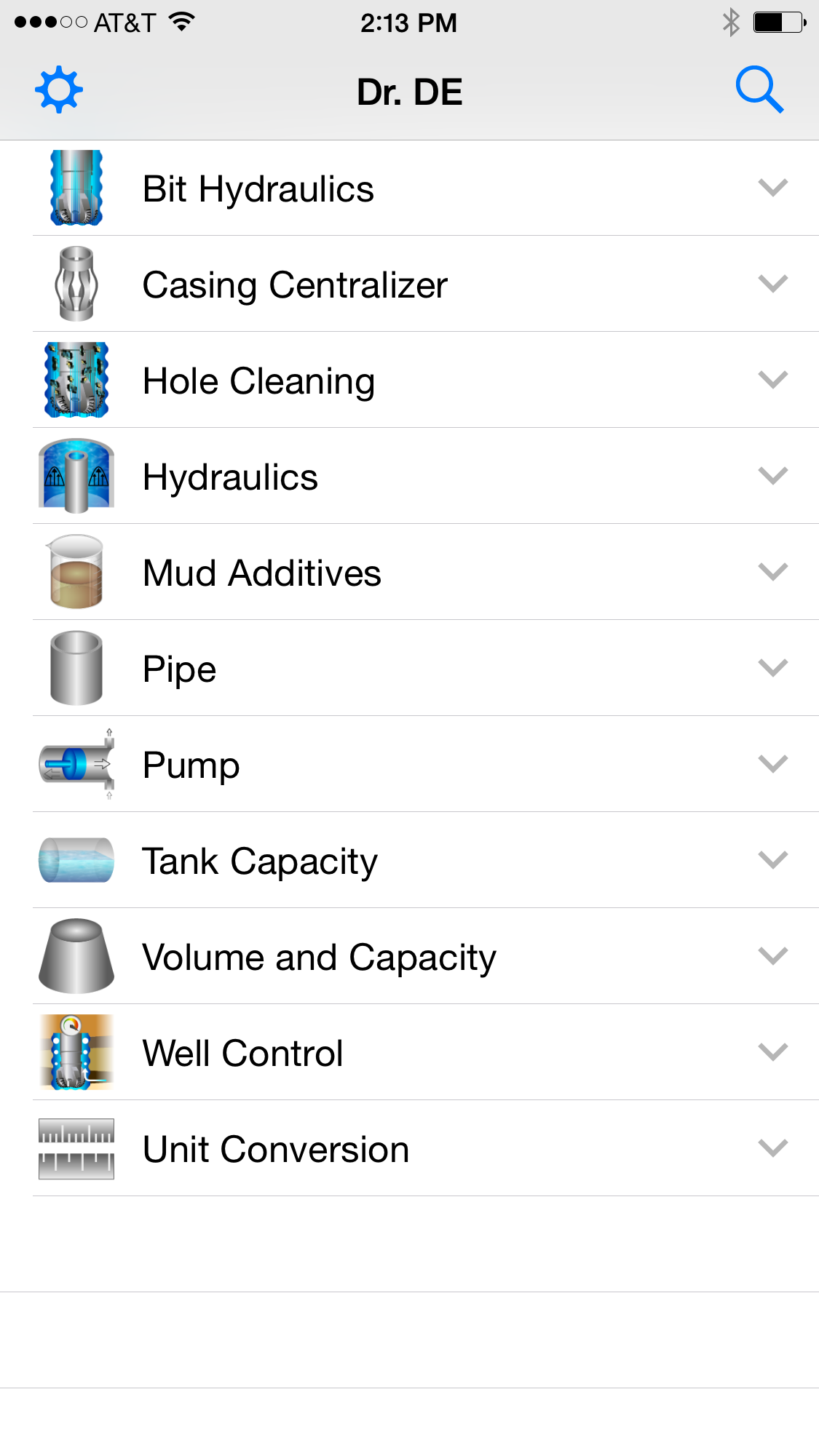

For all these situations PVI has developed a series of software such as:

that can help engineers and operators to perform a better quality job and avoid any potential problems that can put at risk the production.