These days software, in general, becomes more and more user-friendly, even as it gets more and more sophisticated. We, as users, also have more confidence in using software without being bothered to read manuals or attend training sessions. Our busy schedules do not allow us to attend software training.

The situation is the same for drilling software users. As drilling engineers, whether we work in oil companies or in service companies, we always have next wells to drill, meetings to attend and deadlines to meet. We are so busy focusing on output that sometimes we forget about taking the time to receive input and recharge ourselves.

Unlike MS Office, drilling engineering software is not general-purpose software. It requires more specific knowledge to obtain results and understand the meanings of those results. Drilling software training should always be the first step to effectively use a software. Here are the reasons why software training is necessary:

1. Understand the engineering models

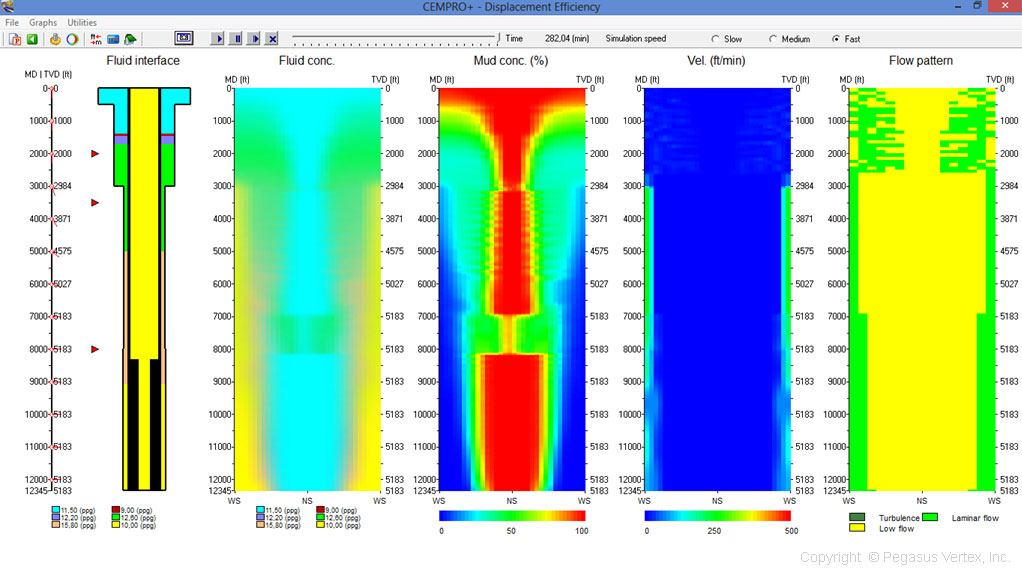

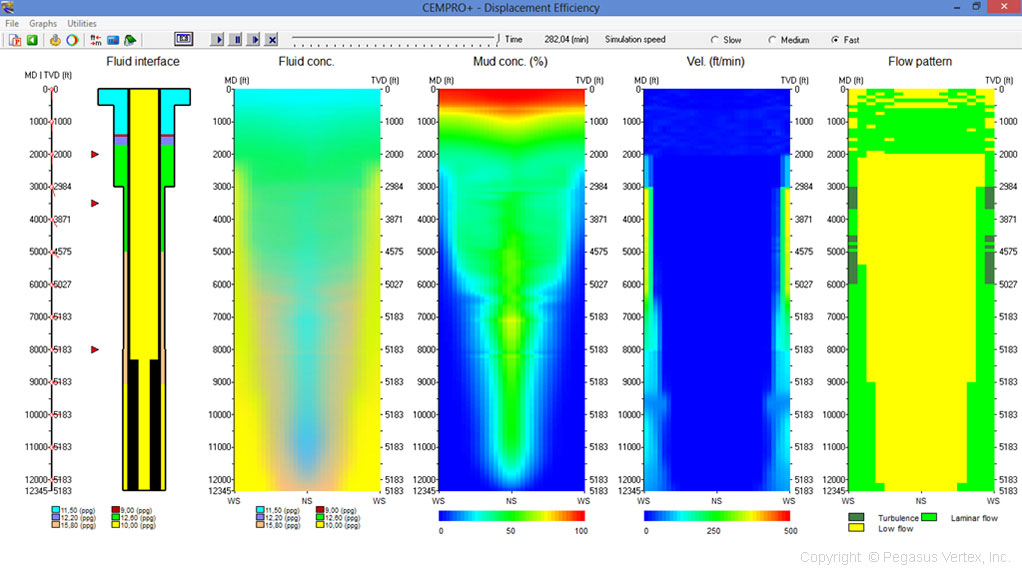

All drilling engineering software is based on certain mathematical and engineering models. Understanding these models behind the graphic user interfaces helps us acknowledge the limitations of the software as well as the capabilities.

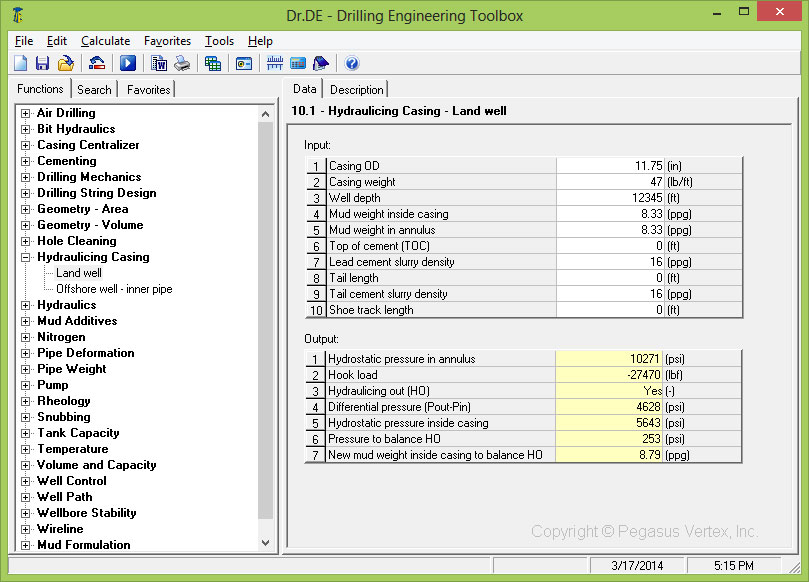

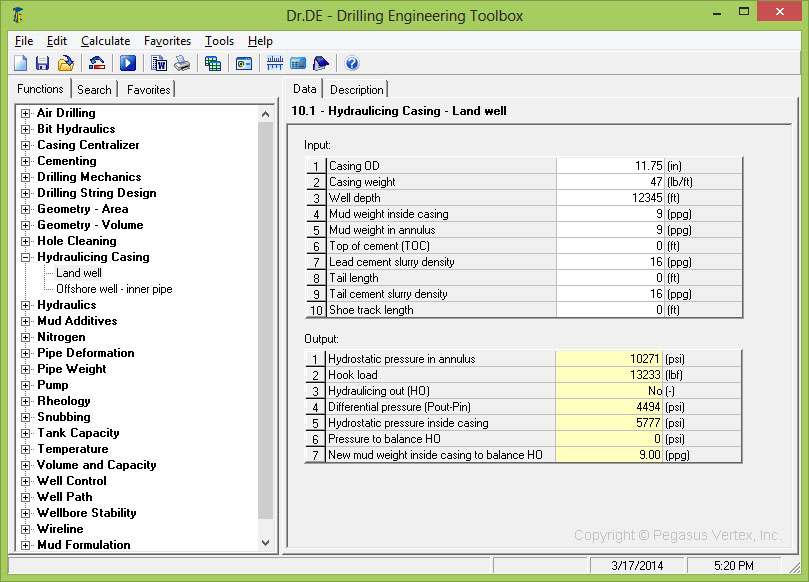

2. Interpret data meaningfully

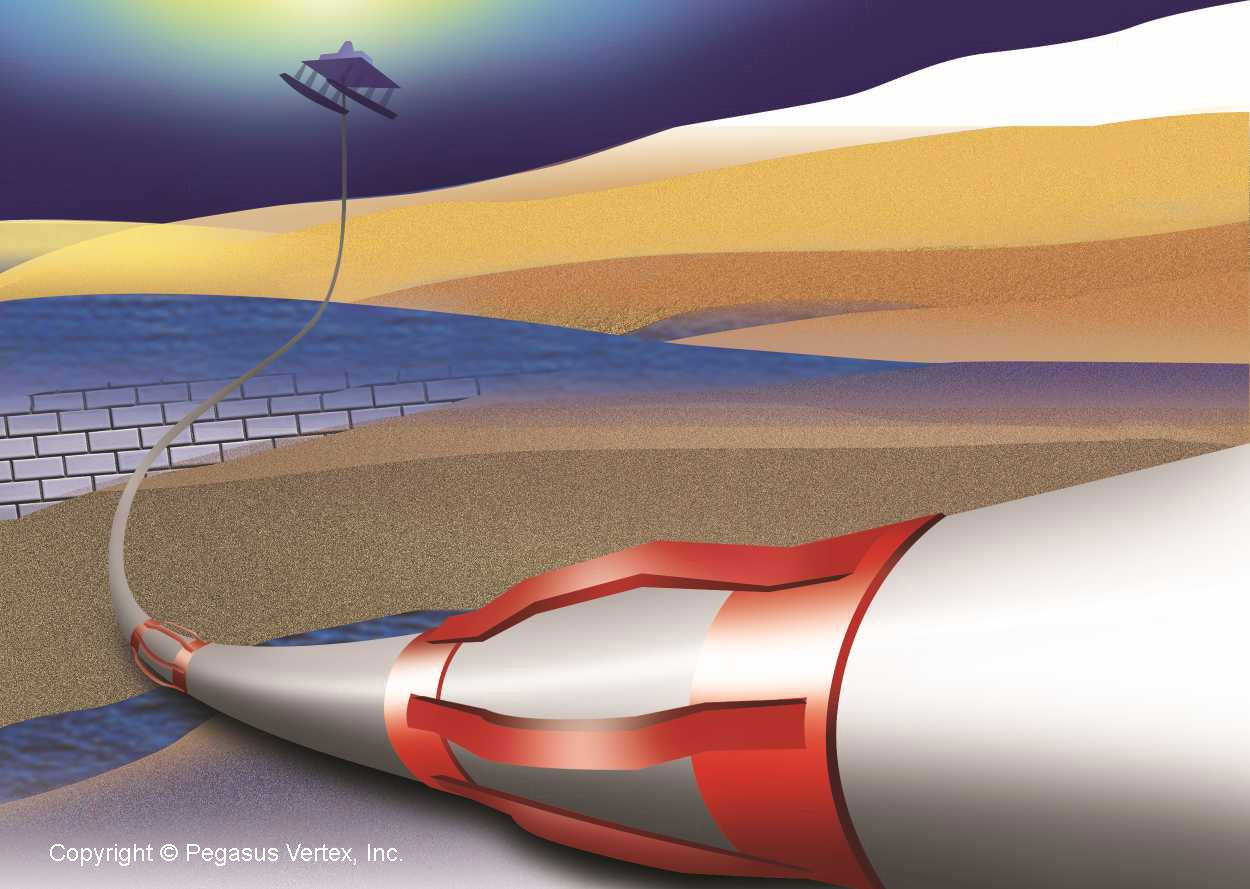

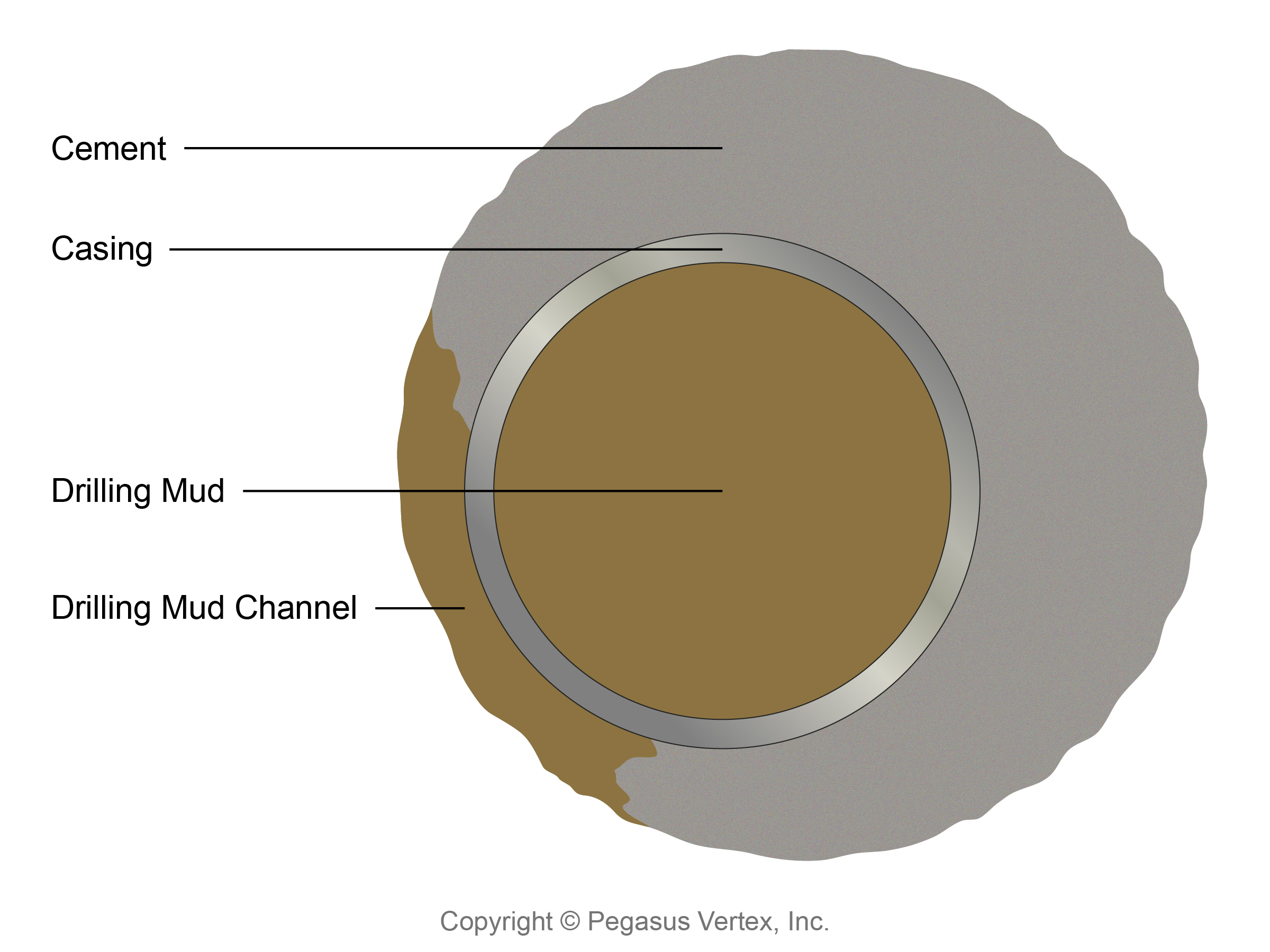

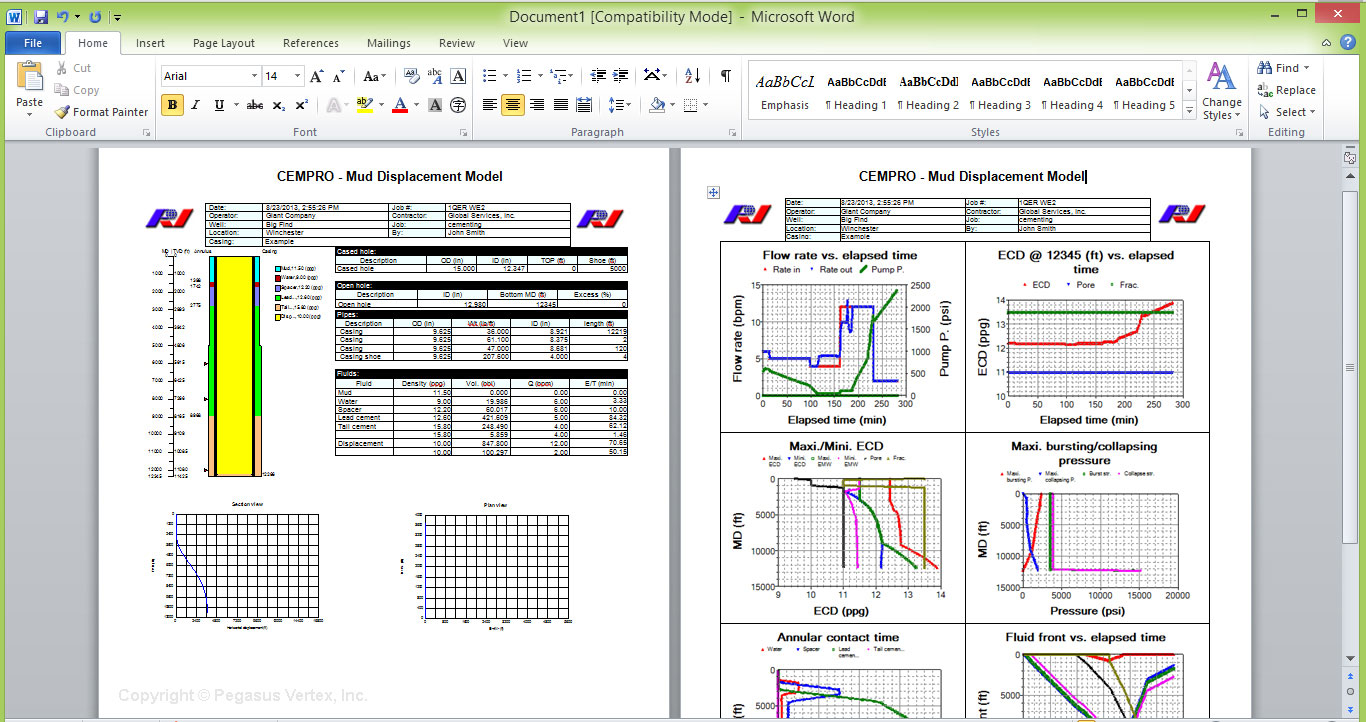

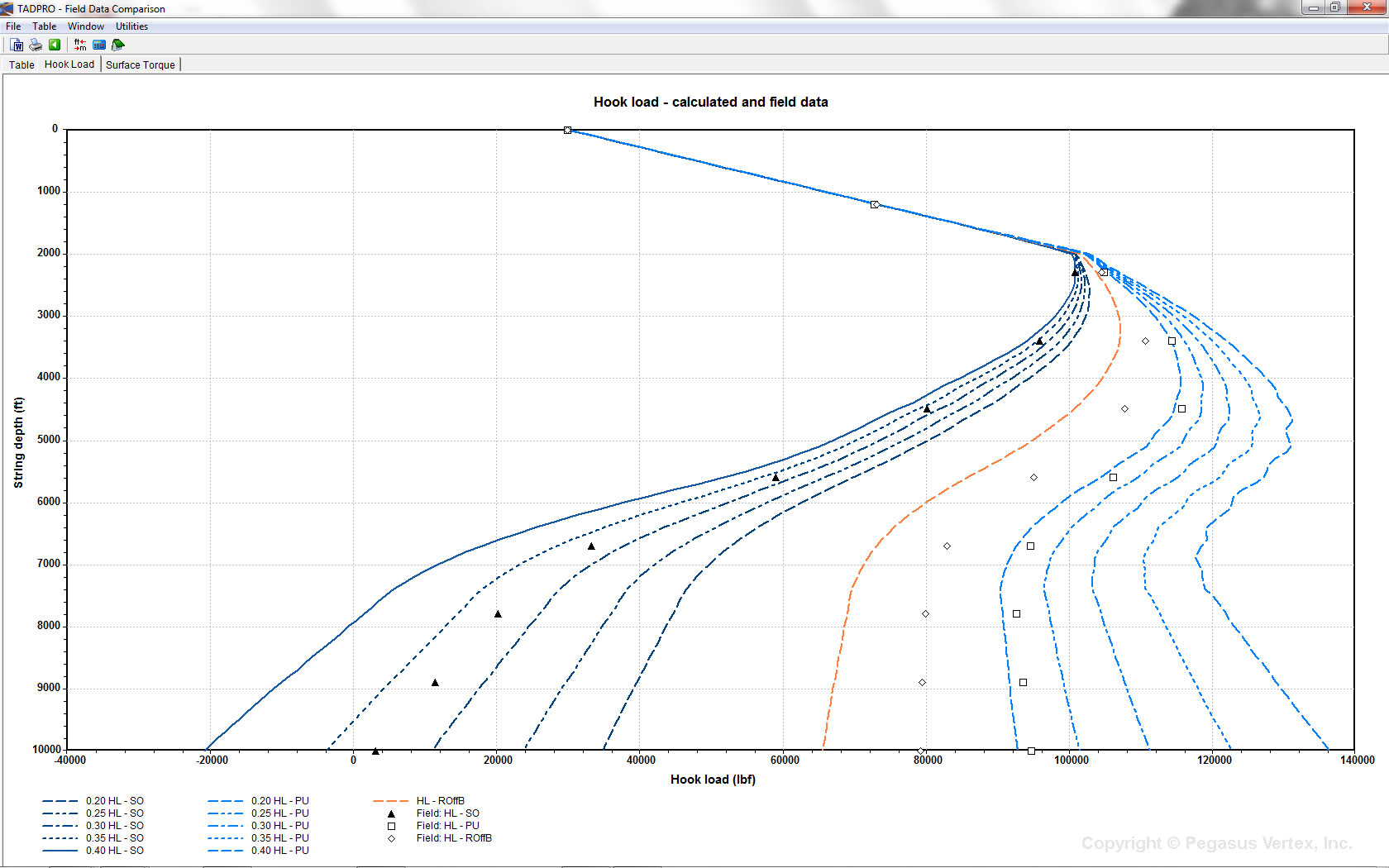

Drilling software needs input data such as survey, BHA, wellbore and mud properties to predict hook load, pump pressure and ECD, etc. Like other software, only meaningful input data can lead to meaningful output data. It is necessary for users to know what the required input data is and to explain the meanings of the output data and charts to their colleagues or clients.

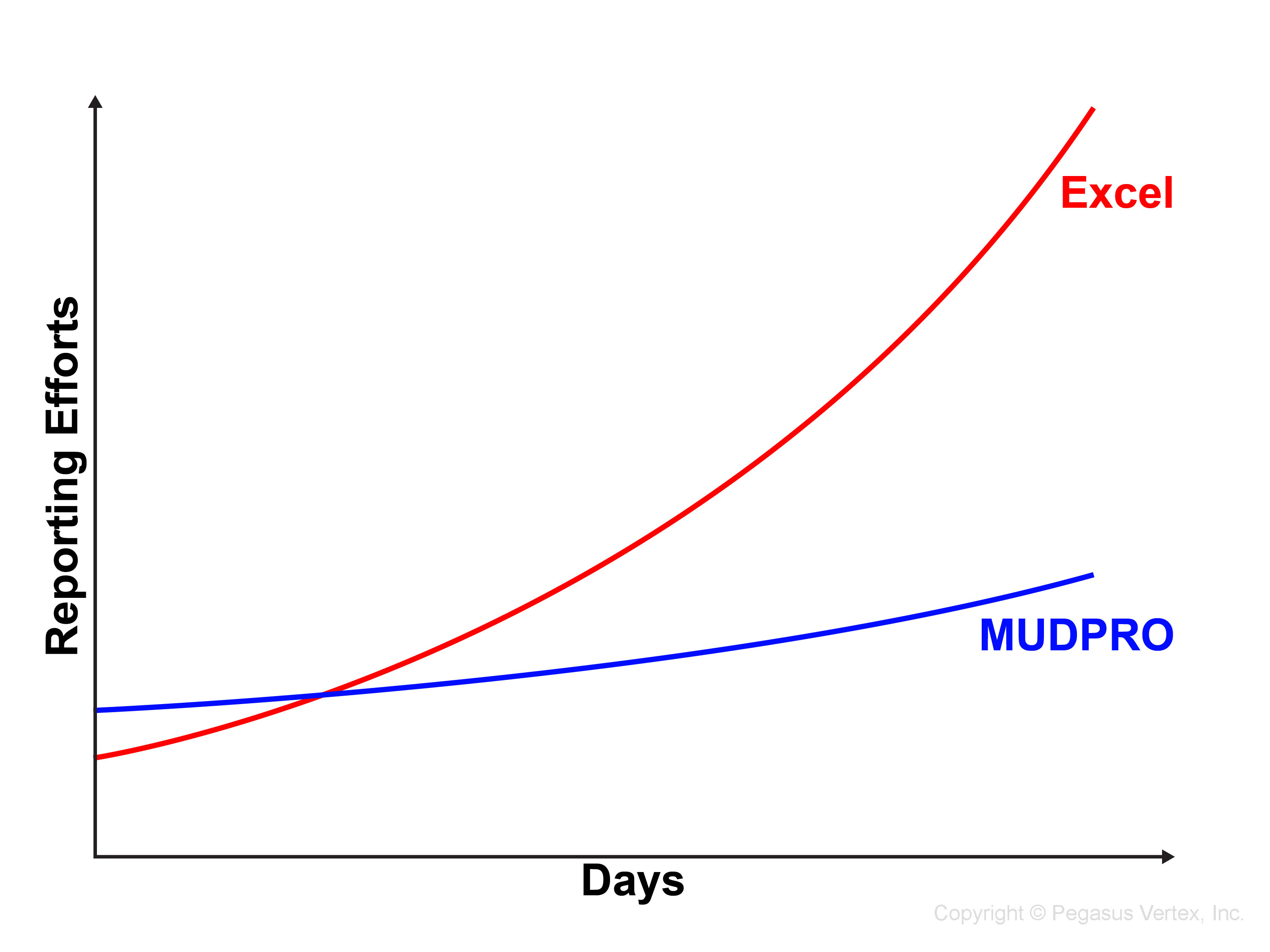

3. Increase efficiency

Training helps potential users to see the big picture as well as the tricks and features of the software. Once users know more aspects of the drilling software, they can use the software more efficiently. For example, survey data is essential to describe the well path and calculate the torque, drag and hydraulics. Survey data can be in various formats, Excel, text or PDF. All of our software can import data from these formats. The survey import feature saves tremendous time, especially when importing survey data from a PDF file.

4. Gain confidence

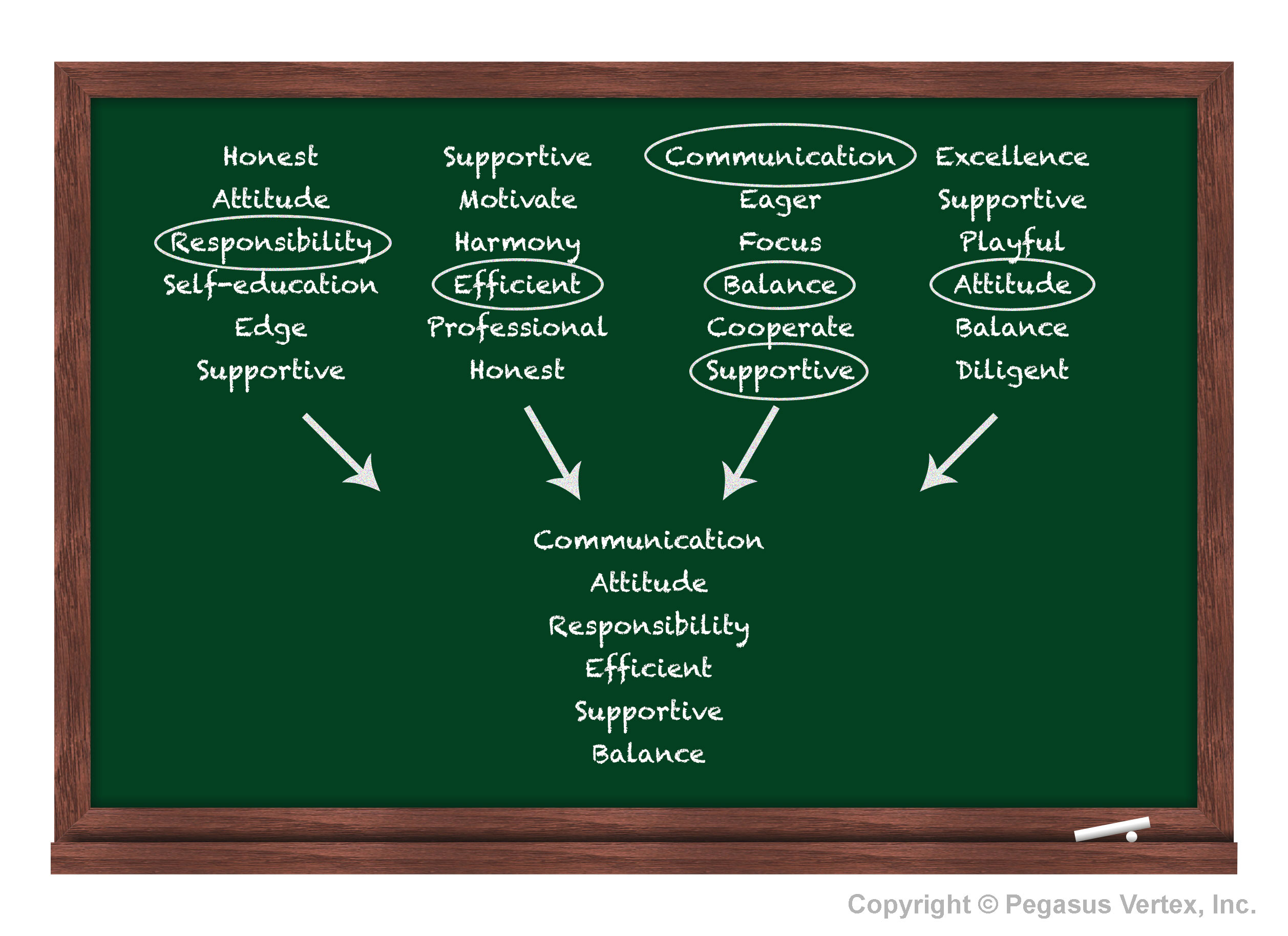

Software training connects the users with the developers of the software. The 2-way communication helps the users understand the ideas and structures of the software. Once users understand the inside calculations, the software is no longer a black box to them. Training removes the mysterious veil of the software. Users become more confident on explaining the results to clients.

5. Guide and influence

The software development training also provides a platform for users to influence and even guide the software development. Users, involved in field operations, can give suggestions, which can enhance the functions. This leads to better versions and win-win situations for software vendors and users.

Ancient Chinese philosopher Confucius once said:

“I hear and I forget.

I see and I remember.

I do and I understand.”

How true this is to drilling software training.