Cementing a well is the procedure of developing and pumping cement into a wellbore. Although it is used for various reasons, cementing protects and seals the well. Very frequently, cementing is used to permanently block out water from penetrating the well. Cementing is also used to seal the annulus after the casing string has been run in the wellbore. In addition, cementing can be used to seal a lost circulation zone, or a specific area where there is a reduction or absence of flow inside the wellbore. When it comes to directional drilling, cementing is used to plug an existing well, in order to run a directional well from that point.

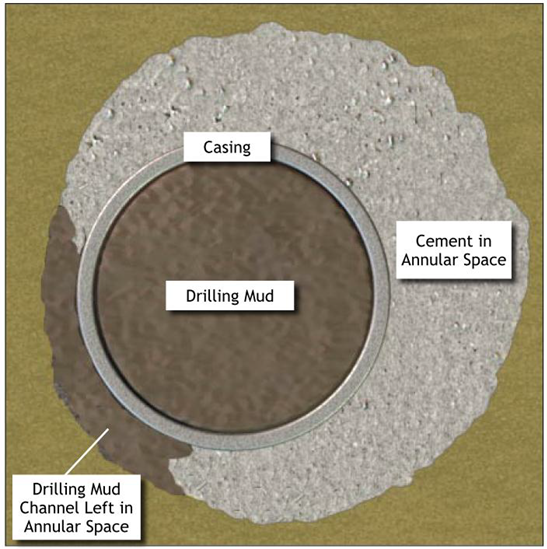

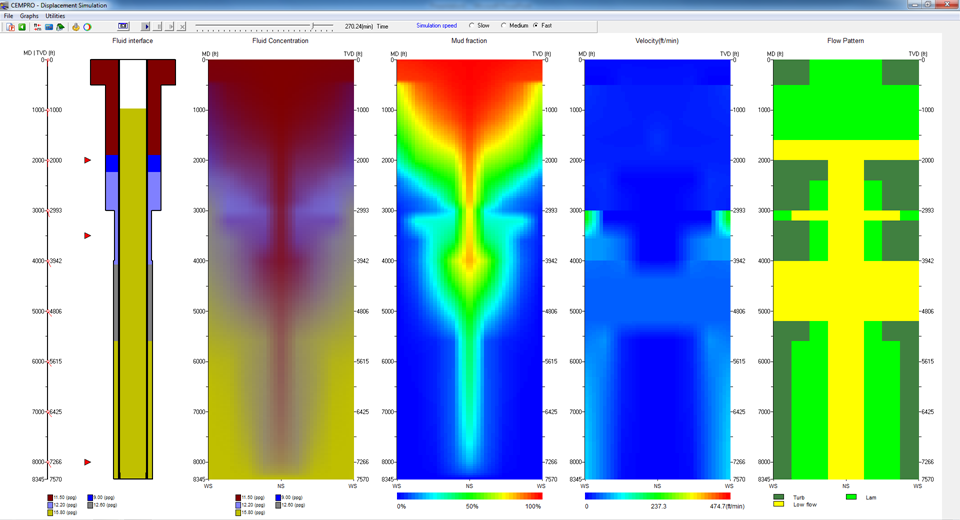

Cementing is performed when the cement slurries are placed into the well by pumps, displacing the drilling fluids that are still located in the well, and replacing them with the cement. The cement slurries flow to the bottom of the well through the casing, which will later be the pipe through which the hydrocarbons flow to the surface. From there it starts filling the space between the casing and the wellbore, and hardens. This permanently positions the casing in place and seals the wellbore so that outside materials cannot enter.

Preparing the Cement

When preparing a well for cementing, it’s very important to be certain of the amount of cement required for the job. This is done by measuring the diameter of the borehole along its depth. Also, to know the required properties of the cement is very essential before beginning any cementing operation. The proper set cement is good to be determined, including the density and viscosity of the material, before actually pumping the cement into the hole.

Special mixers are used to combine dry cement with water to create the wet cement that is also known as slurry. The cement used in the well cementing process is Portland cement, and it is calibrated with additives to form one of eight different API classes of cement. Each is employed for various situations.

Additives can include accelerators, which shorten the setting time required for the cement, as well as retarders, which do the opposite and make the cement setting time longer. In order to decrease or increase the density of the cement, lightweight and heavyweight additives are added. Additives can be added to transform the compressive strength of the cement, as well as flow properties and dehydration rates. Extenders can be used to expand the cement in an effort to reduce the cost of cementing, and antifoam additives can be added to prevent foaming inside the well. In order to plug lost circulation zones, bridging materials are also added. However, the critical part missing here is the management of numerous reports and search function.

Without an efficient lab database, we will face the following situations:

- Difficulty of designing cement slurries.

- Waste of resources to repeat similar tests.

- Lack of prove while job problems occur.

- Non-standard practices at various labs within a company.

To streamline the cement lab operation, PVI developed CEMLab: This software is an integrated database management application that:

This software is an integrated database management application that:

- Formulates slurries.

- Calculates lab amounts for all ingredients, such as cement, dry and liquid additives, salts and water.

- Generates weigh-up sheets.

- Stores API test results.

- Generates lab reports.

CEMLab, is a web based application that allows quick access to all of your slurry formulations and testing statuses from anywhere, at any time. The advanced search function allows users to find the formula and test quickly and brings the previous jobs to their screen in no time. It’s a great tool for preparation.