“Knowledge is power. Information is liberating. Education is the premise of progress, in every society, in every family.”

Kofi Annan (Ghanaian diplomat)

In the petroleum industry the more knowledge we gain the more progress is made. The ability to control the downhole environment while drilling has been a dream held by drilling and reservoir engineers for decades. In the past resent years, drilling engineers focused on preventing influx of formation fluid or gas, and weighted-up their mud accordingly, but as a result, drillers found themselves indeed between the rock and a hard place.

In the early 1970s a better knowledge of drilling hydraulics started being developed. Up to this point, hydrostatic pressure and formation temperature were derived by measuring static mud weight and viscosity at the surface and calculating a pressure gradient which could be extrapolated to bit depth. Formation temperature was also calculated from a gradient. Neither parameter was precisely known. In addition, every time the mud pumps were stopped to make a connection a pressure surge was initiated when the pumps were re-started. In a formation with a tight drilling margin, this pressure spike could break down a weak spot and cause loss of circulation. Contrarily, when the drill pipe was pulled to make a bit trip or even a short trip, care had to be taken not to swab-in the well.

Drilling decisions focused on extending bit life to the maximum rather than maximizing ROP. This was accomplished by using less-aggressive bits to mitigate vibration which is the leading cause of bit wear. Float valves were installed just above the drill bit to prevent the loss of drilling fluid and to force the seawater mixture and cuttings coming down the annulus to enter the fractures. Thanks to the knowledge acquire through the years new technology has risen. Cutting-edge techniques, sustained by innovative technology, are increasing the industry's ability to safely and efficiently drill unstable formations in deepwater.

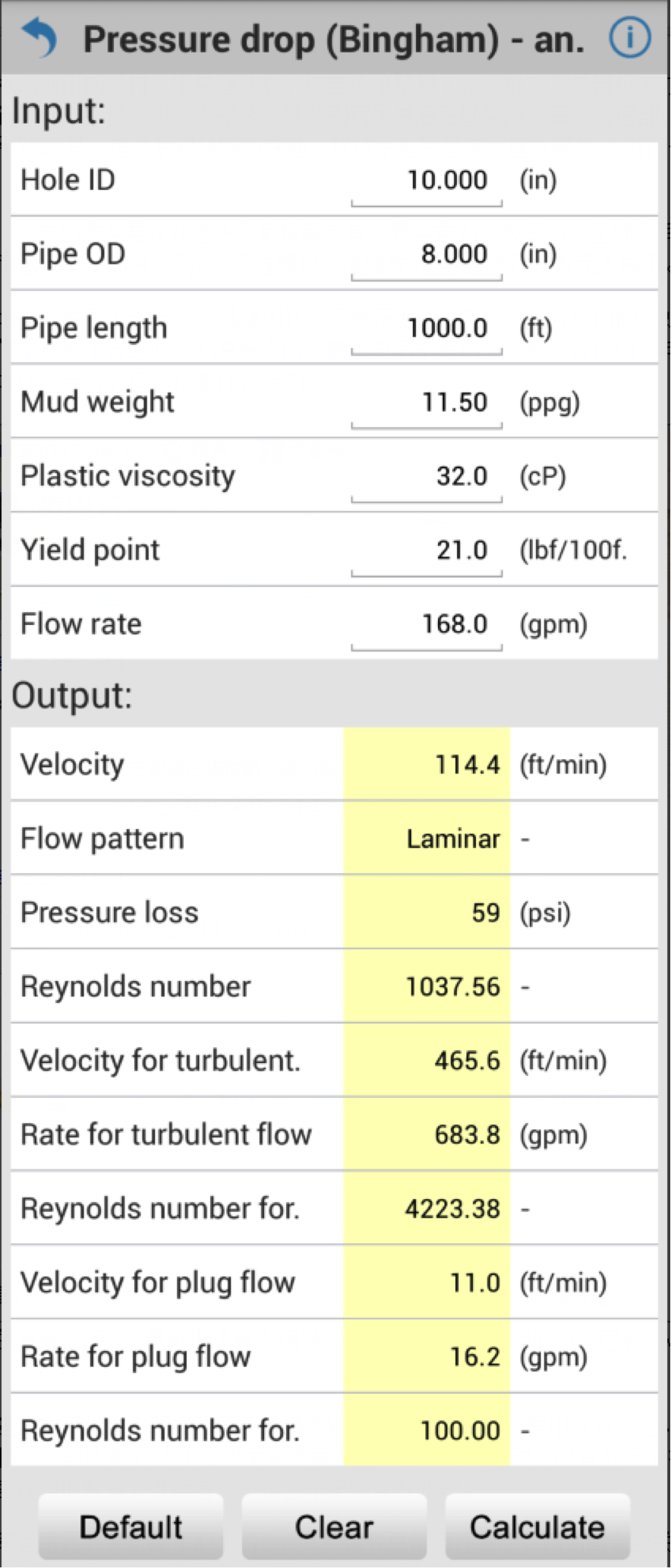

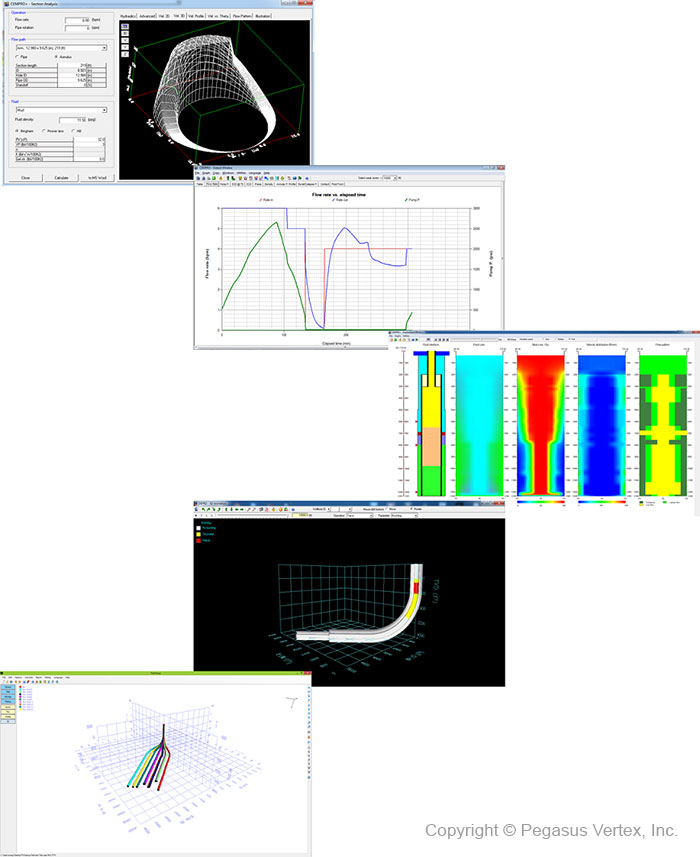

The ability to measure precisely and monitor continuously the equivalent circulating density of drilling fluid at the bit is essential for success. This is one of the functions of HYDPRO, PVI’s drilling hydraulics model.

This software’s ability has allowed major strides in drilling technology that have affected safety, cost effectiveness, and efficiency. Many of the previous problems can be traced by more accurate estimations of dynamic downhole conditions.

This software’s ability has allowed major strides in drilling technology that have affected safety, cost effectiveness, and efficiency. Many of the previous problems can be traced by more accurate estimations of dynamic downhole conditions.

Other functions of HYDPRO include:

- Surge and Swab

- Bit Optimization

- Hole Cleaning

- Volumetric Displacements

Like most critical undertakings, prior planning is a given. Even modular systems that are relatively easy to implement on a standard drilling unit must be carefully sized and can benefit from as much prior reservoir knowledge as possible. The benefits are important and well worth the planning effort.