Louis D. Brandies once said:

“Most of the things worth doing in the world had been declared impossible before they were done. Impossible means that you haven’t found the solution yet.”

A little over 100 years ago there were things that were considered impossible to do and that there was no way they could ever be achieved. For instance, to be able to fly among the clouds, but was it really an impossibility? Time proved that it wasn’t.

Just like flying among the clouds was impossible to do once, there are many things that thanks to the advancement of technology now are possible. For instance, a few decades ago horizontal or extended-reach drilling was considered impossible as well as casing wear prediction. In these environments, casing design is critical to a safe and successful drilling operations and well production, and unexpected casing wear can result in significant costs or even the loss of the well itself. This is the problem that drilling companies want to prevent.

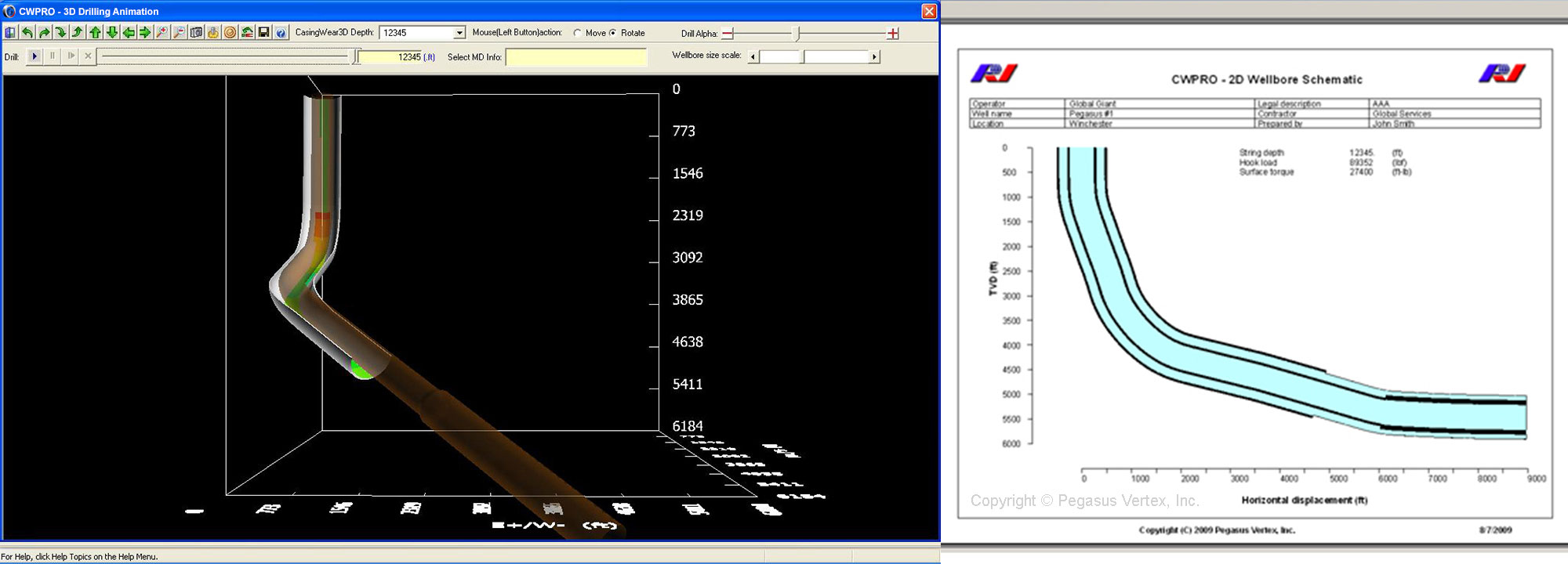

So the question is: Is there any tool or software to calculate and predict casing wear severity? Yes there is! It’s called CWPRO.

This casing wear model uses the number of drill string rotations and contact force between the drill pipe and casing to calculate wear. The contact force is calculated using the dogleg severity inside the well. The maximum dogleg severity frequently determines the location and extent of the most severe casing wear. CWPRO helps operators and service companies identify, control and prevent potential problems. In overall the goal of CWPRO is to more accurately quantify casing wear risks and to ensure that the integrity of the casing is maintained during drilling operations.

Like mentioned before, there are many things that were considered an impossibility not too long ago like for instance, flying among the clouds. Likewise, thanks to software like CWPRO, predicting casing wear is no longer impossible; it is a fact.