The demanding industry today continues to drill progressively challenging and costly wells, through more challenging formations.

Every year, operators lose hundreds of millions of dollars in their attempt to resolve drilling problems such as shock and vibrations, damage to bits and under-reamers, poor hole cleaning, borehole washouts, stuck pipe, plugged drillstrings and poor or inconsistent drilling performance. An analysis of worldwide drilling operation failure statistics in 2012 showed that a 38% were associated with stuck pipe, 27% caused by shock and vibration and 9% due to drillstring plugging.

Severe downhole drilling dynamics and vibration cause drillstring failures that can incur significant amounts of non-productive time. Drillers must trip out of hole either to replace bits or damaged bottom hole assemblies, perform fishing operations or drill costly sidetracks. Poor performance and reduced rates of penetration can occur when there is sufficient transfer of power to the bit, when cutting structures wear out permanently, or when rigsite personnel apply overly conservative drilling parameters due to a lack of trustworthy real time actionable information on downhole conditions.

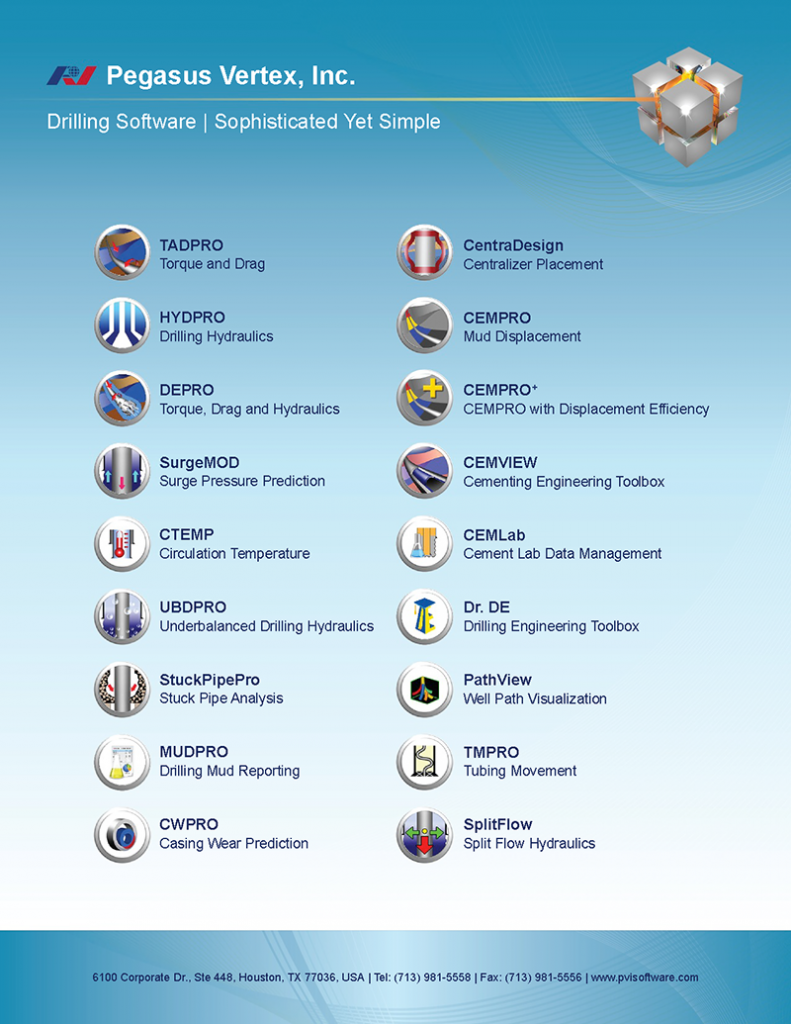

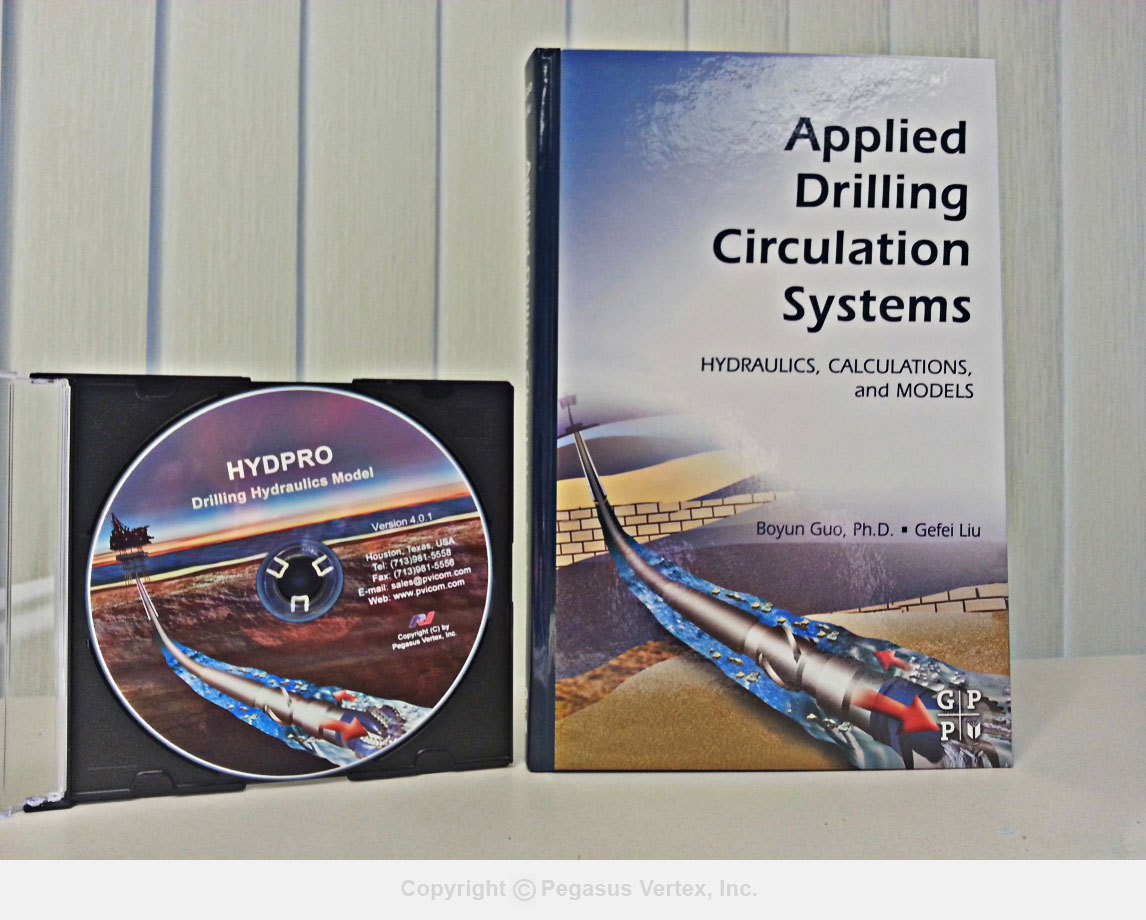

PVI has a variety of software packages that can be an smart solution for many of these situations that operators and service companies have to deal with. For example, the software can help users to effectively reduce risks by quickly identifying the type and severity of downhole motions, detecting poor hole cleaning or sticking pipe probabilities at an early stage, plus many more. For directional drilling, users can enhance borehole quality, assist casing running and manage wellbore tortuosity. Users can also increase drilling performance by selecting drill parameters that increase the drilling efficiency and improve overall rate of penetration among many other things. For both onshore and offshore, PVI software can perform engineering calculations that optimize business and technical decisions and also provide quality engineering consulting and customized development.