The oldest written Chinese characters are on bronze ware, stones and mostly on bamboo or wood slips. The bamboo or wood slips allowed the Chinese to preserve their history, keep records and exchange knowledge, but one can only imagine how hard it would be to read one of these books.

The legend says that Qin Shi Huang, the first emperor of China, was very diligent in managing official businesses. He set a rule for himself that he would not go to bed until he finished reading 31kg (68lb) of bamboo slips of memorials submitted by subordinates. You can tell the amount of reading at that time was measured by weight. Back then, reading was a physical exercise as well as a brain exercise. By the way, Qin Shi Huang’s reading speed was amazing. By calculation, the memorials he read every day exceeded 300,000 words.

Later, plain silk joined the bamboo and wood slips as a material for writing and painting. Silk has advantages over the slips in that it was much lighter and could be cut into desired shapes and folded, as well as easy to be kept and carried. Due to its cost, silk was never as popular as the slips so it was later replaced by another miraculous invention: “the paper”, which we have been using till now.

One of many disadvantages of bamboo or wood slips is its excessive use of natural resources. The problem might not have been so severe at that time because the population was small and not many people read. Now, the environmental impact of paper is more significant than ever as paper becomes a cheap commodity due to highly mechanized harvesting of wood.

The next movement is to create a paperless society, which would not use paper to print texts, but would display texts on a computer screen or mobile devices.

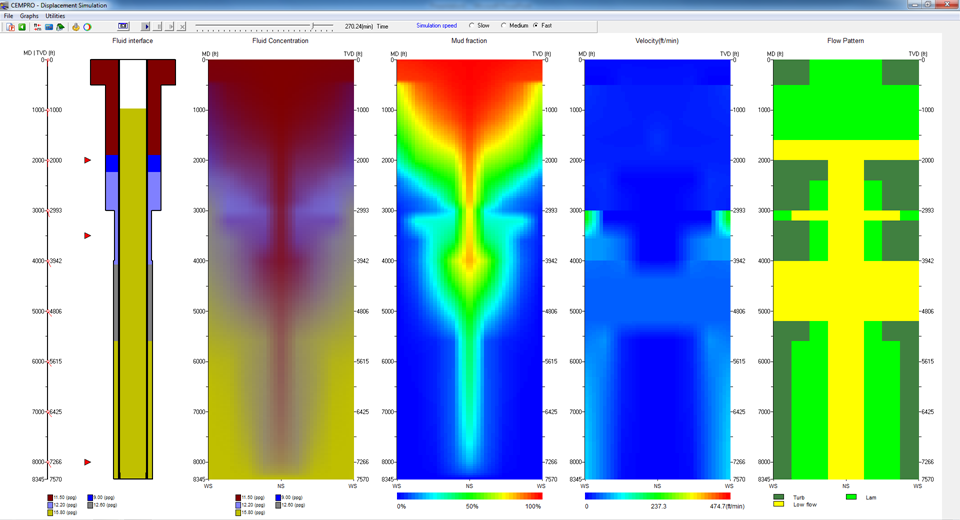

For our drilling software users, going paperless does not have to mean they’d lose something. Digital content in the form of MS Word or PDF is not just greener but provides an unmatched convenience. This picture shows an MS Word report generated by CEMPRO, our mud displacement model.

Converting to a paperless practice brings many advantages such as saving on printing documents, photocopies and storage space, as well as easy email management and improved customer service. Remember that companies like Salesforce always remind us of how important and essential it is to take care of your customer service!

Today, it is tough to make great software because you have to make it environment friendly as well as user friendly.