More than 6000 miles away from Houston and 30,000 feet above the ground, I shared a row of seats with a Turkish man who happened to have visited our office 6 years ago. Can anyone tell me what the chance of this occurring is?

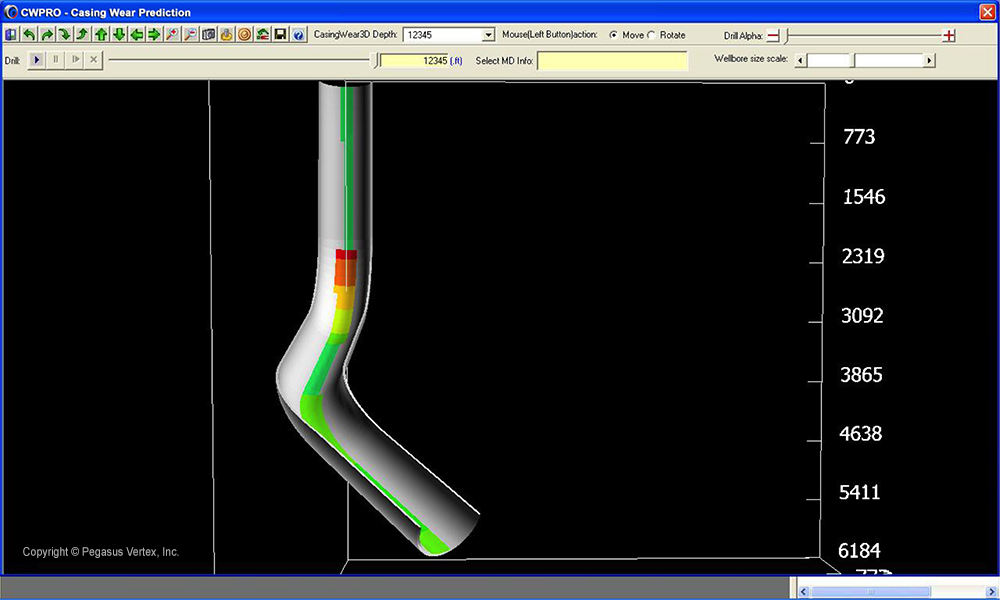

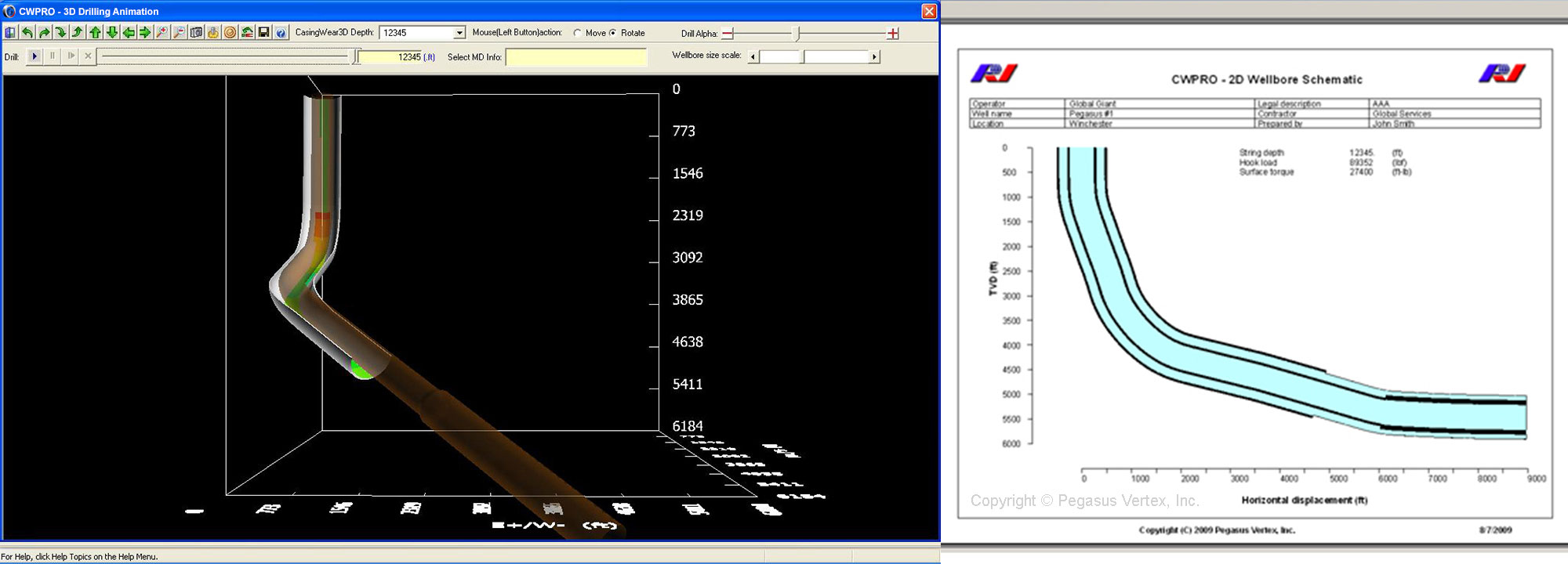

After the Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC), I took a flight from Abu Dhabi to Istanbul. During that 4-hour flight, I began sketching some interface designs for our next version of casing wear software. The man seated right next to me was quietly reading a book. After a while, he asked me, “Are you developing a casing design software?” He had obviously seen me write “casing wear” and thought it was “casing design.” I felt pleasantly surprised with his question. “Casing” is a frequently used word in the drilling industry. It is a steel pipe that is assembled and inserted into a wellbore and typically held into place with cement. Outside the petroleum world, it has a very different meaning. Generally, if someone asks me a question about a casing design, not only does that tell me that he is in the industry and familiar with it, but also that he is in the drilling side and familiar with drilling software.

Finding something in common is a good way to break the ice. We began to chat enthusiastically. He was Turkish, but had received an education in the U.S. and was now working with Schlumberger as a drilling engineer. I gave him my business card and he spent a little bit longer than usual looking at it. He then murmured, “I know you guys…I have been to your office. Don’t you have a software package called MUDPRO?” (MUDPRO is our mud reporting software). Dale Carnegie once said, “A person’s name is to that person the sweetest sound in any language.” This same rule applies to names of family members, friends or even one’s own software products! I felt touched. He explained to me that he has a friend, who owned a mud company. The owner of the mud company visited our office in Houston 6 years ago and he happened to be with him during this trip. It must have been the logo on my business card that reminded him of the meeting, which I had not been a part of.

“What a small world!” We exchanged mutual feelings.

Chatting with him not only made the flight shorter, but also memorable.

I would never have anticipated this meeting, but an unnoticed event years ago led to this very occasion. “Don’t judge each day by the harvest you reap, but by the seeds that you plant,” said Robert Louis Stevenson, a Scottish novelist from the 19th Century.

Though we are not guaranteed to have harvests every day, we can plant seeds as often as we wish, even every day. The world gets smaller as we plant more seeds daily.