Since November 2019, I have been writing and editing a book titled “Applied Well Cementing Engineering” with Elsevier, a Netherlands-based publisher specializing in scientific, technical, and medical content.

I have the pleasure of working with some top experts who contributed 11 chapters. They are; Dr. Jiang Wu, Alfredo Sanchez, John McCormick, Gunnar DeBruijn, Sarah Whitton, Prof. Boyun Guo, Dr. Hu Dai, Joseph Shine Jr., Kirk L. Harris, and David Poole. I appreciate that Mr. David Stiles, of ExxonMobil Upstream Integrated Solutions, wrote the foreword. Collectively, our team of authors brings together knowledge from over 250 years of experience in cementing and condenses it into this book. Elsevier will publish the first edition on May 1, 2021.

I want to thank Ms. Katie Hammon of Elsevier for the inspiration and trust, and Ms. Ruby Gammell of Elsevier for the editorial assistance.

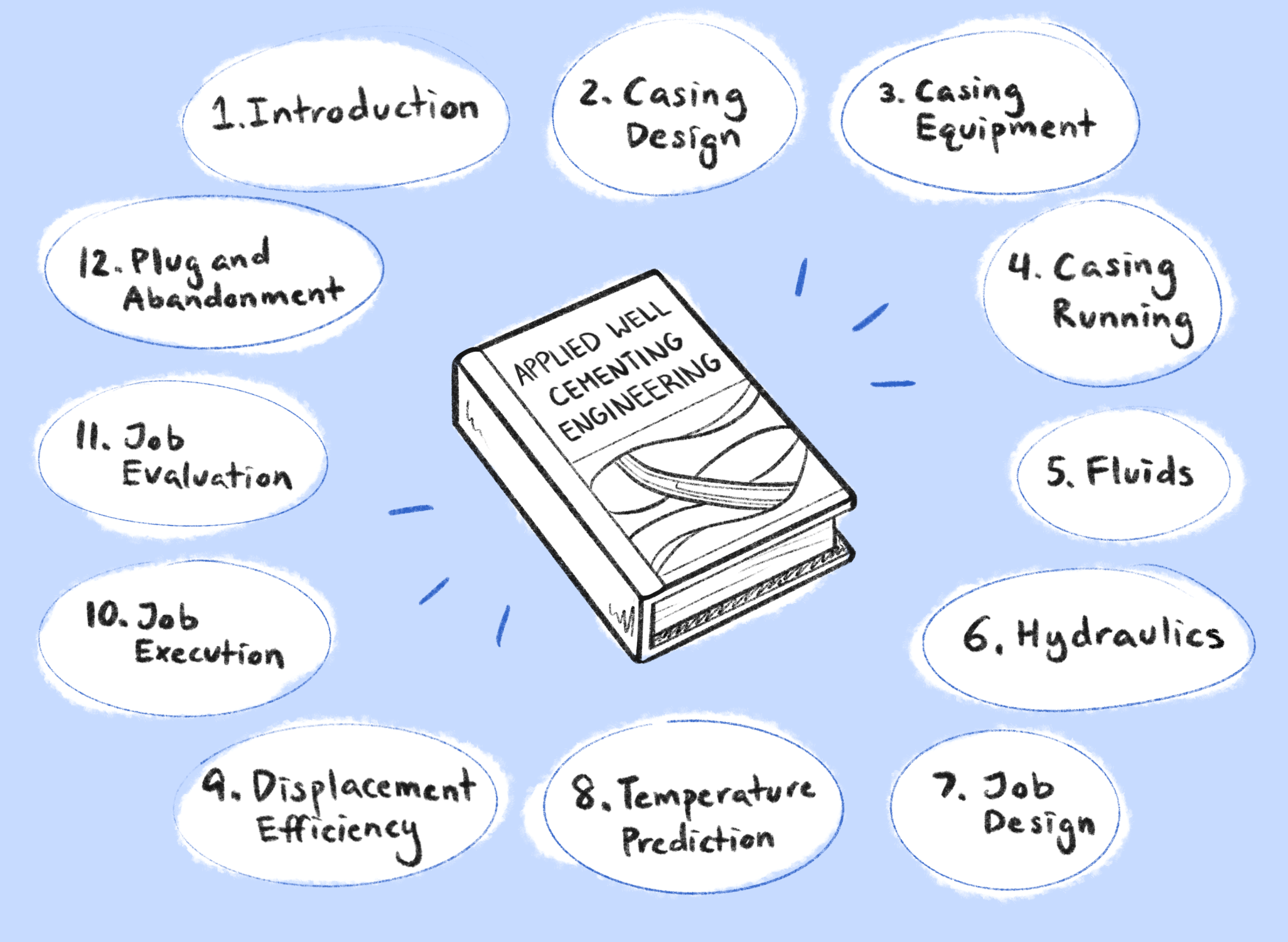

The goal of this book is to help readers gain the complete framework of a cementing job with a detailed roadmap from casing design to plug and abandonment.

To pre-order: https://www.elsevier.com/books/applied-well-cementing-engineering/liu/978-0-12-821956-0

I would be happy to mail you a complementary CEMSheet, if you send me a photo of the receipt of your book order with your mailing address. CEMSheet created by PVI, is a cheat sheet containing more than 2,000 data related to cementing engineering. Additionally, we will cover the shipping fee.