CWPRO - Casing Wear Prediction Model

CWPRO - Casing Wear Prediction Model

- Overview

- Features

- Resources

- Specification

Casing wear is a continuous concern during the process of drilling and workover. Casing integrity relies highly on the preliminary casing design, which requires to consider both well path and casing sustainability to withstand all the operations. Improper placement of casing may end up in catastrophic incidents such as oil spills, blowouts or even the loss of a well. Remediation of casing failures can raise the field operation cost dramatically and be time-consuming.

CWPRO is integrated with multi-well sections, multi-operations, cumulated casing wear results and tool joint wear models. As a result of extensive research from experimental and theoretical perspective, CWPRO is developed to better understand the casing wear process, predict the location and magnitude of casing wear and give constructive suggestions.

Passing on Pegasus Vertex’s belief in building ‘Sophisticated Yet Simple’ software, CWPRO maximizes utilization of your valuable data, and frees the engineers from dealing with all the abundant casing wear calculations and complicated logics. Install CWPRO to ensure building a safe and successful well.

- Wear factor sensitivity analysis

- Casing wear calculation

- Tool joint wear calculation

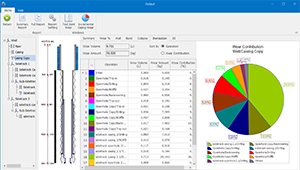

- Torque and drag calculation

- 3 well types: land, offshore, and offshore with riser

- 5 operations: drilling, back reaming, rotation off bottom, tripping in and tripping out

- Parent well with sidetracks

- Multiple casings and open holes for each well/sidetrack

- Cumulative casing wear from multiple operations

- Initial wear

- Burst and collapse strength calculation

- 3D well path visualization

- Survey tortuosity

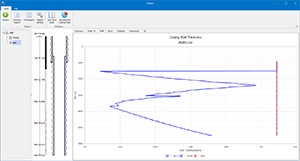

- Casing wear schematics

- Pipe protector recommendation

- Survey import from Excel®, text or PDF® files

- US oil field, SI and customized units

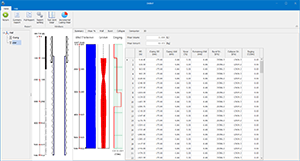

- Screenshots

- Brochures

- White Paper

- FAQ

Q1. Can the software calculate collapse strength of worn casings?

Yes. For worn casings, a factor of the worn casing collapse strength to the new casing collapse strength will be calculated first. Then this factor will be used to obtain the collapse strength of the worn casing.

Q2. How do I select an appropriate wear factor?

Wear factor is affected by mud type, mud additive, whether lubricants are applied, casing interior, tool joint protector material if protectors are placed…CWPRO provides suggested wear factor based on the joint-industry project, DEA-42.

User can also get the wear factor from the manufacturer if any wear factor reduction tool is placed.

Q3. How does CWPRO deal with cumulative casing wear caused by different drill string operations?

CWPRO is intelligent enough to handle complicated casing structures and abundant operations inside the casing. During each operation, the software would define the exposed area between a casing and a drill string to calculate the exact wear. Casing condition after one operation would be the initial condition for the next operation. Casing wear accumulates in the sequence of operations.

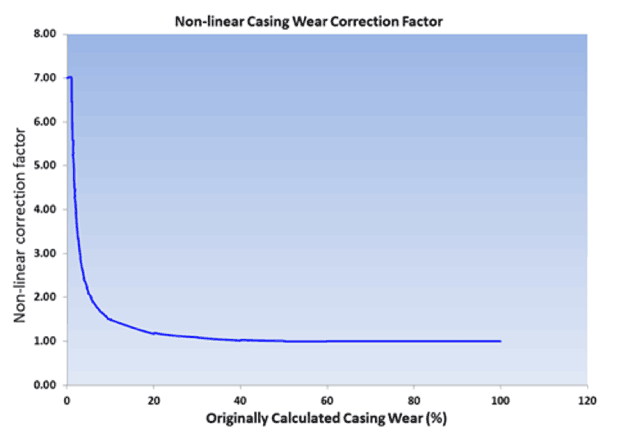

Q4. When to apply non-liner correction to wear calculation?

The default casing wear calculation uses linear wear factor, meaning that casing wear increase linearly with time. But experiments have shown that the wear factor decreases with increasing wear depth and wear time. As casing wear increases, casing wear speed decreases and eventually stables when wear exceeds about 50%.

If the casing wear result is small (less 5%), it is suggested to apply the non-liner correction. The illustration of this non-linear correction factor is shown below.

-

Operating Systems

- Microsoft Windows® 10 or above

-

Microsoft Office®

- 2016 or above

-

Processor

- Dual core processor, 1.4 GHz or higher. Not compatible with ARM processor

-

Memory

- 4 GB RAM

-

Disk Space

- 200 MB of free disk space for installation

-

Display

- 1,280 x 768 display resolution

-

Installation Options

- Setup file can be accessed from a download link or installation CD provided by PVI