Let’s illustrate in an easier way what torque and drag is:

Hold your index finger tightly in the fist of your other hand.

Now twist your finger.

Do you feel how your finger does not want to twist?

Yes!

You know why?

Because it's not built to be twisted.

The pain you feel is because of the torque you are putting on the joints. - That's torque.

Do you feel how your finger resists the pull because you have a good grip on it with your fist? - That's drag.

Torque and drag can have a dramatic increase in horizontal and extended-reach wells and can become the limiting factor in determining the horizontal length or extended-reach of a well. For this reason, precise calculations of torque and drag are necessary for drilling operations. Torque and drag are the results of friction caused by a moving pipe inside the wellbore: torque occurs when rotating the pipe along the wellbore and drag occurs when moving the pipe.

When drilling horizontal or extended-reach wells, excessive torque and drag may become troublesome both in the drilling operations and later in the completion operations. Estimating torque and drag is very important, but the calculation of drag in the build section of a well is complicated by the effect of the axial force (tensile or compressive) on the lateral contact force which produces the sliding drag and in turn causes changes to the axial force itself. The axial force has a great effect on the torque and drag calculations in the build section. When the axial force (tension or compression) becomes large enough to let the pipe contact only one side of the wellbore, the torque and drag in the build section will increase proportionally with the increase in the axial force.

The most common way to calculate approximate torque and drag values in the build section involves monotonous numerical calculations: dividing the build section into many small pieces, assuming the axial force remains constant in those small pieces, calculating the friction factor for each of the pieces, and then summing these values to get the total drag over the entire build section. This process is both time-consuming and difficult for field engineers.

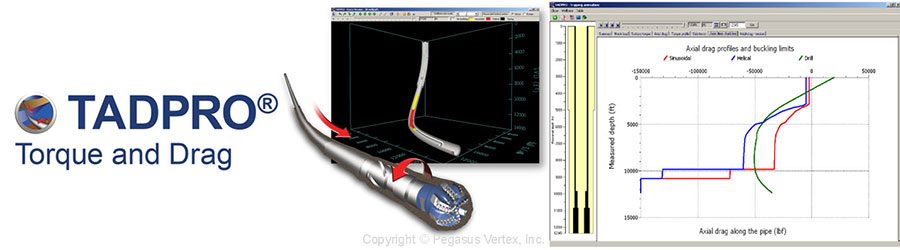

The analysis of torque and drag is made easier by today’s technology. There is a comprehensive torque and drag software in the market that removes many of the risks during the drilling process. This software was developed by PVI and it’s called TADPRO (Torque and Drag).

This software comes with features that help users to:

- Calculate hookload and surface torque

- Identify potential buckling

- Perform sensitivity analysis

- Determine side force

- Analyze forces downhole

- User-friendliness and graphical outputs

Illustrations have always been a great learning method and today we have learned two things:

- Fingers were not made to be twisted.

- Likewise a pipe is not built to be twisted, but the torque and drag inevitably occurs during horizontal drilling, but with the help of TADPRO, torque and drag can be calculated and predicted, therefore the risks are reduced.