Cementing operations represent one of the more crucial aspects regarding well integrity. Despite the vast amount of research and the large number of operations throughout the years, well integrity problems, during and after cementing jobs, is something the industry still faces. These problems have been experienced by the petroleum industry globally and can occur at any moment of the well’s life cycle. Well integrity issues have been categorized according to the moment at which they happen:

- During the cement displacement in the wellbore.

- After the cement placement.

- After the cement has been cured.

The first category may result in very serious well-control problems, including blowouts. During the period between 1992 and 2006, the leading cause for blowouts was cementing. These problems usually occur because of improper design of the cementing operations due to hydrostatic pressure of the cement slurries, failure when mixing the slurries to obtain the desire density, and lost circulation during the cement displacement.

The second category is normally associated with the loss of hydrostatic pressure of the cement slurries during the initial hydration period. This also can cause we-control problems, pressure build up in the annulus between the casing strings and zonal isolation problems eventually and the remedial solutions for this are normally expensive and difficult.

The last category refers to long-term problems normally caused by poor cementing jobs. Defective drilling mud removal during the cement slurry displacement in the annulus, insufficient cement height that may lead to casing leakage and corrosion problems are some of the factors that can contribute to long-term well integrity failures and the cost to fix these problems are highly expensive.

PVI has taken into consideration these types of problems and has created two great software for these situations: CEMLab and CEMPRO+.

This integrated database management application formulates slurries and calculates lab amounts for all ingredients such as cement, dry and liquid additives, salts and water. It also generates weigh-up sheets, stores API test results and generates lab reports. CEMLab allows quick access to all slurry formulations and testing statuses from anywhere, anytime.

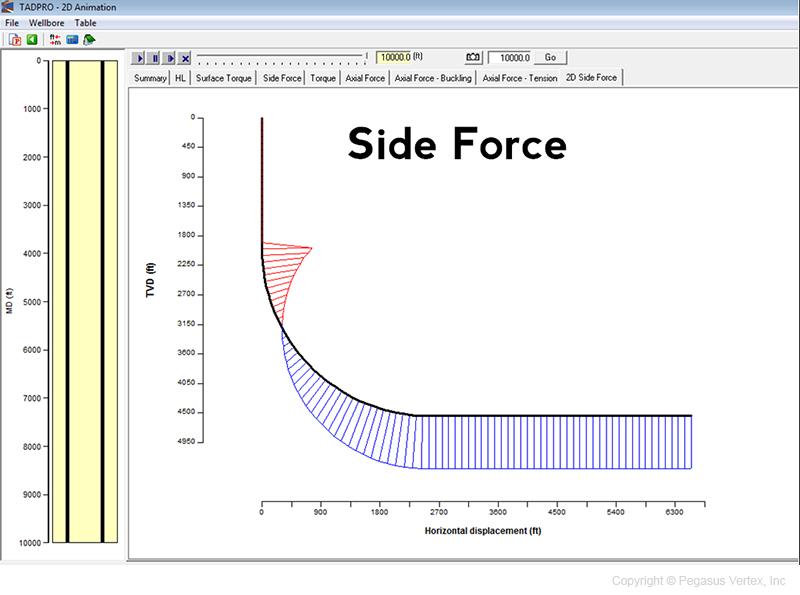

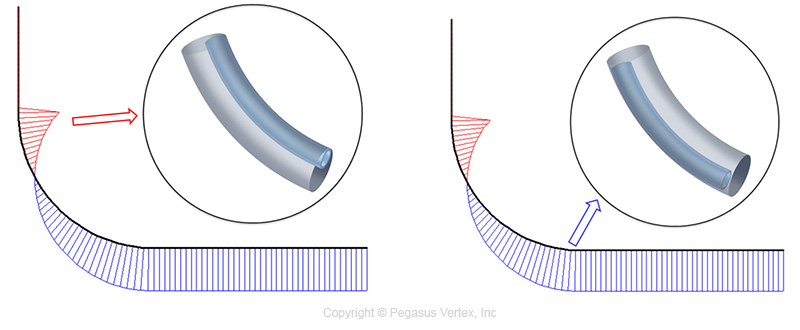

This mud displacement program has the capability of displacement efficiency modeling. Designed for land, offshore, conventional and/or foamed operations, CEMPRO+ accounts for many factors that can affect the efficiency of a displacement job including fluid properties, pumping rates, casing standoff and complex wellbore geometry. CEMPRO+ is the must have software for cementing operations.

Before designing your next well, keep these two models in mind to help you achieve, from the designing of the slurries to the mud displacement, a successful cementing operation.