Friction, the resistance force between two rubbing surfaces, the very drag consumes our energy while we walk, run and drive, also prevents us from falling, colliding and accident.

Friction is everywhere. We can see it painting on roads when car makes sudden stop. We can hear it screaming when wheels stop rotating while car keeps the momentum. We can smell its anxiety when Native Indians rotate drive in wood making fire. These are some appearances of friendly sides of friction. And sometimes, we need to amplify its power by the means like the following.

For downside, we have seen plenty in our daily lines. Our shoe wears out (so our feet do not). We dress smart phone up by putting screen or cover so that scratch (a form of friction) only damages the dress, not the body.

This is friction: we hate, love and cannot get rid of it. And we had better use it toward our advantage.

In drilling and completion practices, we encounter friction whenever we move tubular inside wellbore. When moving pipe downward such as in drilling and casing running, friction slows us down. If we move pipe upward such as in trip-out, friction is pulling pipe down. Yes, friction always acts in the opposite direction of the moving object.

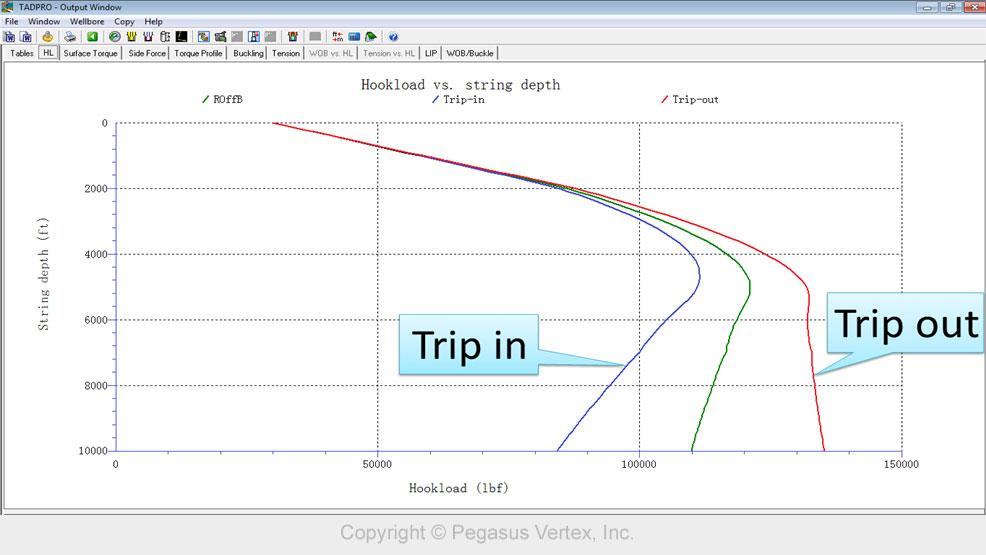

In torque and drag analysis, one graph is worth noting: the hookload for trip-in and trip-out operations, as shown here.

The green line is the hookload when pipe is stationary inside wellbore at various depths.

The blue line shows the hookload when pipe is moving downward. The red line is the hookload when pipe is moving upward.

Note that during trip-in, the frictional drag is against the gravitational force, so the hookload is smaller than the hookload during trip-out, when the frictional drag acts with the gravitational force.

In other words, during trip-in, friction helps hook to hold the pipe weight, while during trip-out, the friction is on the same side of gravitation to make hookload higher.

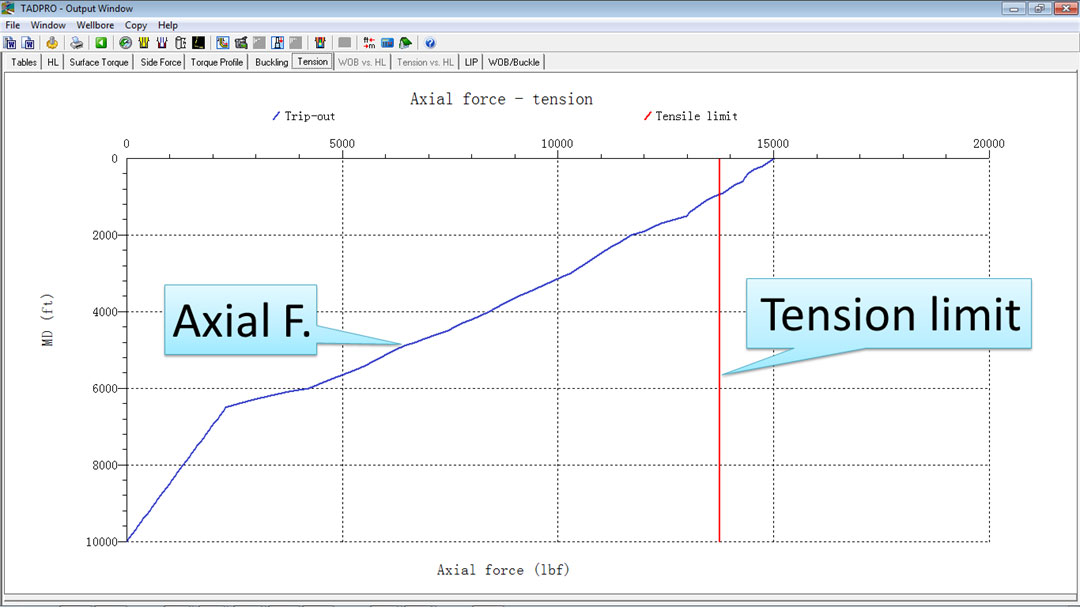

For coiled-tubing (CT) operation, since CT has relatively thin wall (could be as small as 0.125 inch), the tensile limit of CT may not withstand the pulling of drag and weight during trip-out, as shown in the following graph.

We can run the CT into a deviated well. However, we may not be able to pull the same CT out of the hole!

Friend or foe, friction shows up in various fashions. We just need to know his characteristics and dance with him.