Recently, I have been thinking about writing another article. It seems as though whenever I take a trip, it is my most productive time when it comes to writing. Trips lead to many occurrences, which are a good source for topics.

My journey to Abu Dhabi to attend ADIPEC (Abu Dhabi International Petroleum Exhibition and Conference) had just started, but it had already generated a couple of interesting ideas. On my way to the airport, I suddenly realized that I forgot to check if my passport was in my bag. I pulled my car to the shoulder of the highway. Before I stopped the car, I heard a loud noise coming from the front tire. I secretly wished that I had just hit an abandoned tennis ball. I stopped the car, opened my trunk, and checked my bag. I cannot believe my eyes when I saw the tires are flat when I just got them shined yesterday using the product I got from https://www.grandprixtimes.com/best-tire-shine.

My passport was there, as it was supposed to be, but my right front tire was flat. Long story short, I spent the next hour driving my disabled car to a parking lot, calling AAA and my wife, who drove me to the airport. I caught my flight in time, leaving the whole ordeal to my wife. Even when looking at the photo I took of my car, I can still smell the burnt rubber.

I always thought that events like this were unlikely to happen. Or if it did happen, it would most likely happen to someone else.

I should have checked my travel essentials ahead of time. Or perhaps I should have picked a more secure place to stop, or even better, I should have a little bit of faith on myself in getting my travel documents in place. I just chose a wrong time to pull my car to a wrong place. “A little bit preparing saves lots of trouble. I could almost hear my flat tire complaining.

Incidentally, the book I read on my flight, called “The Power of Persuasion” by Robert Levine, talks about the illusion of invulnerability overoptimism. Here are some research examples from the book:

- People who feel at risk for health problems are more likely to gather disease prevention information.

- Smokers who minimize their own risk of disease are less likely to try quitting.

- People in high earthquake risk areas who downplay danger are more likely to live in poor structures.

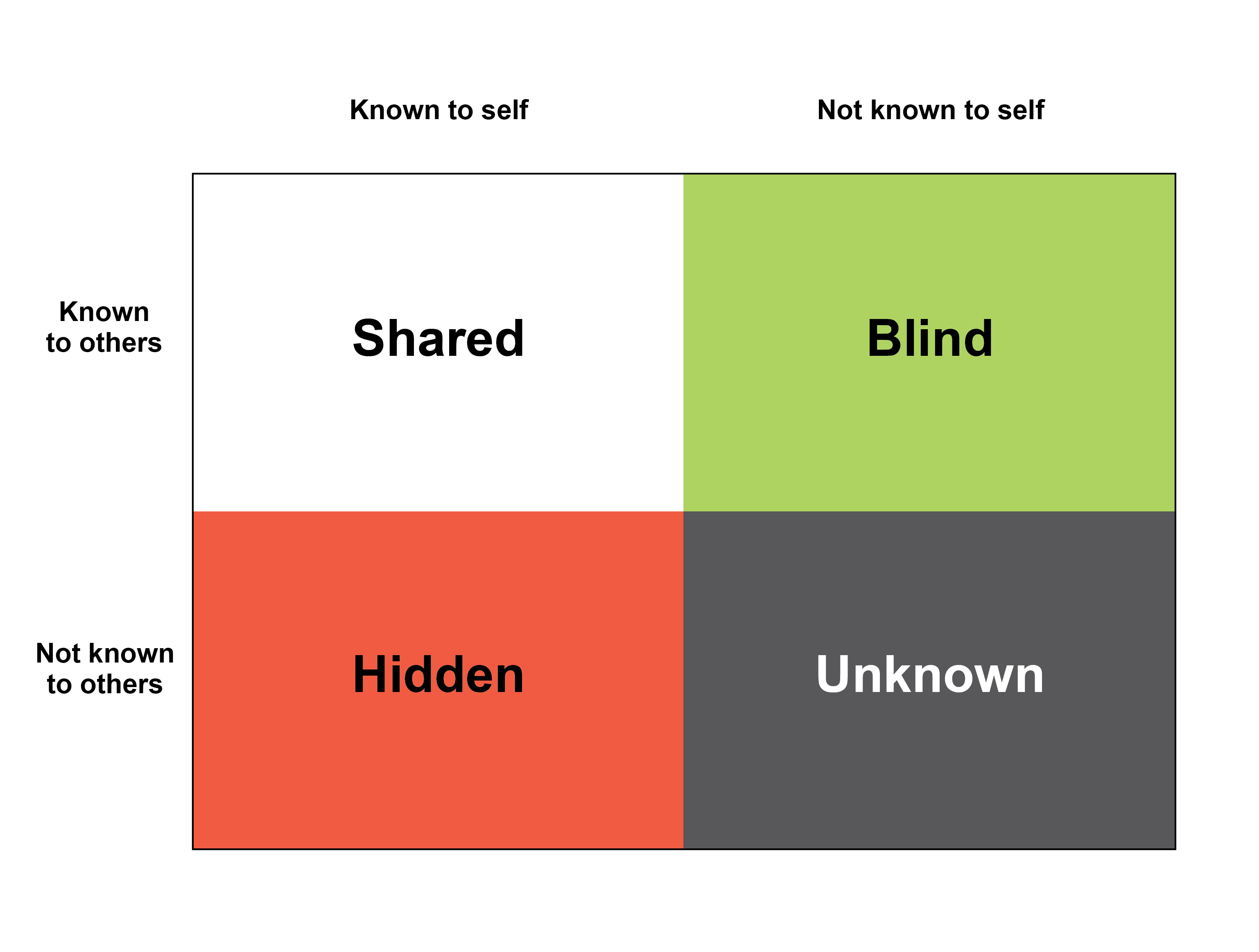

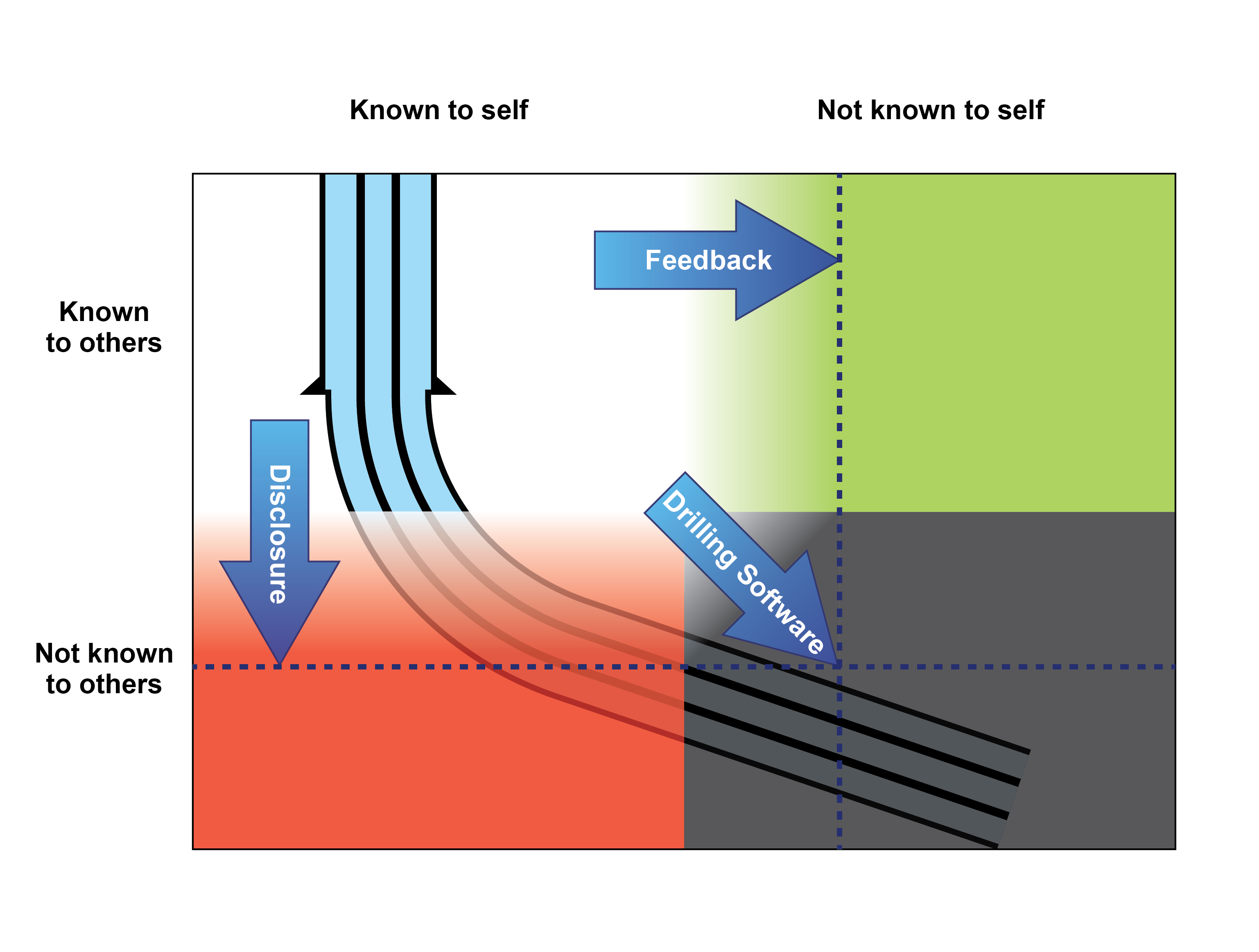

The book just listed a few. Real world examples are everywhere. For instance, within our drilling community, if we use an analogy of the above sayings, it would go something like this:

- Drilling engineers who feel the risk of drilling issues arising are more likely to prepare for potential problems.

- Engineers who minimize potential problems are less likely to prepare for or identify them.

As the geneticist David Searls observed, “The tendency for an event to occur varies inversely with ones preparation for it.” I learned my lesson the hard way.