Drillstring drag is the cumulative force required to move the pipe up or down inside the hole. Torque is the movement required to rotate the pipe. Drag forces usually are paralleled to the string weight measured with the string rotating but not reciprocating. Measured from the rotating string weight, the pickup drag is usually vaguely greater than the slack-off drag. The magnitudes of torque and drag are related in any particular well; high drag forces and excessive torque loads usually occur together. There are various causes for excessive torque and drag, such as tight hole conditions, keyseats, differential sticking, sloughing hole, sliding wellbore friction and cuttings buildup caused by poor hole cleaning.

With the exception of sliding friction, these causes are associated with problem conditions in the wellbore. Contrarily, in wells with great hole conditions, the primary source of torque and drag is sliding friction. Torque and drag from any source tend to be more troublesome in extended-reach directional wells. In very deep, highly deviated wells, overcoming torque and drag can be vital to the successful well completion. The capability to predict frictional loads on drillpipe has two main benefits:

- Deep, highly deviated wells can be planned to minimize torque and drag and ensure successful drilling operations to total depth.

- A more complete knowledge of drillstring loading allows use of improved drillstring design techniques, having considered the extra forces involved.

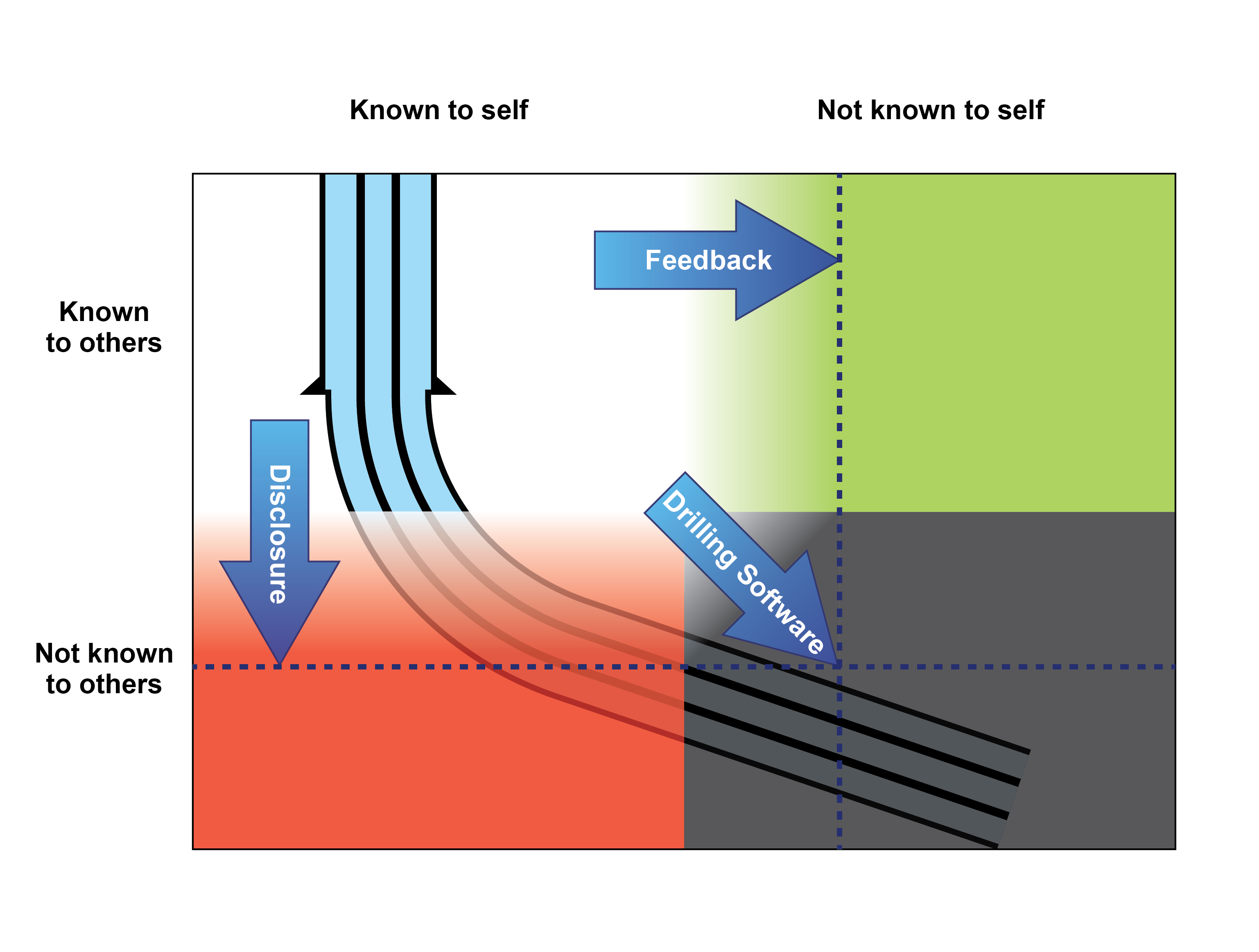

Both torque and drag are assumed to be caused entirely by sliding friction forces that result from contact of the drillstring with the wellbore. Two factors affect sliding wellbore friction:

- The normal contact force

- The coefficient of friction between the contact surfaces

The product of these two factors represents the magnitude of the sliding friction force. The normal contact force between the pipe and hole wall depends on several factors such as, the effects of gravity on the pipe, the effects of tension acting through curvatures in the wellbore and even pipe bending. The sliding friction coefficient is the ratio of the friction force to the normal contact force. This factor depends on specific contacting materials and on the degree of lubrication at various places in the wellbore. However, the oil and gas industry has made many advancements technologically speaking and quite a few models have been developed for these kind of issues.

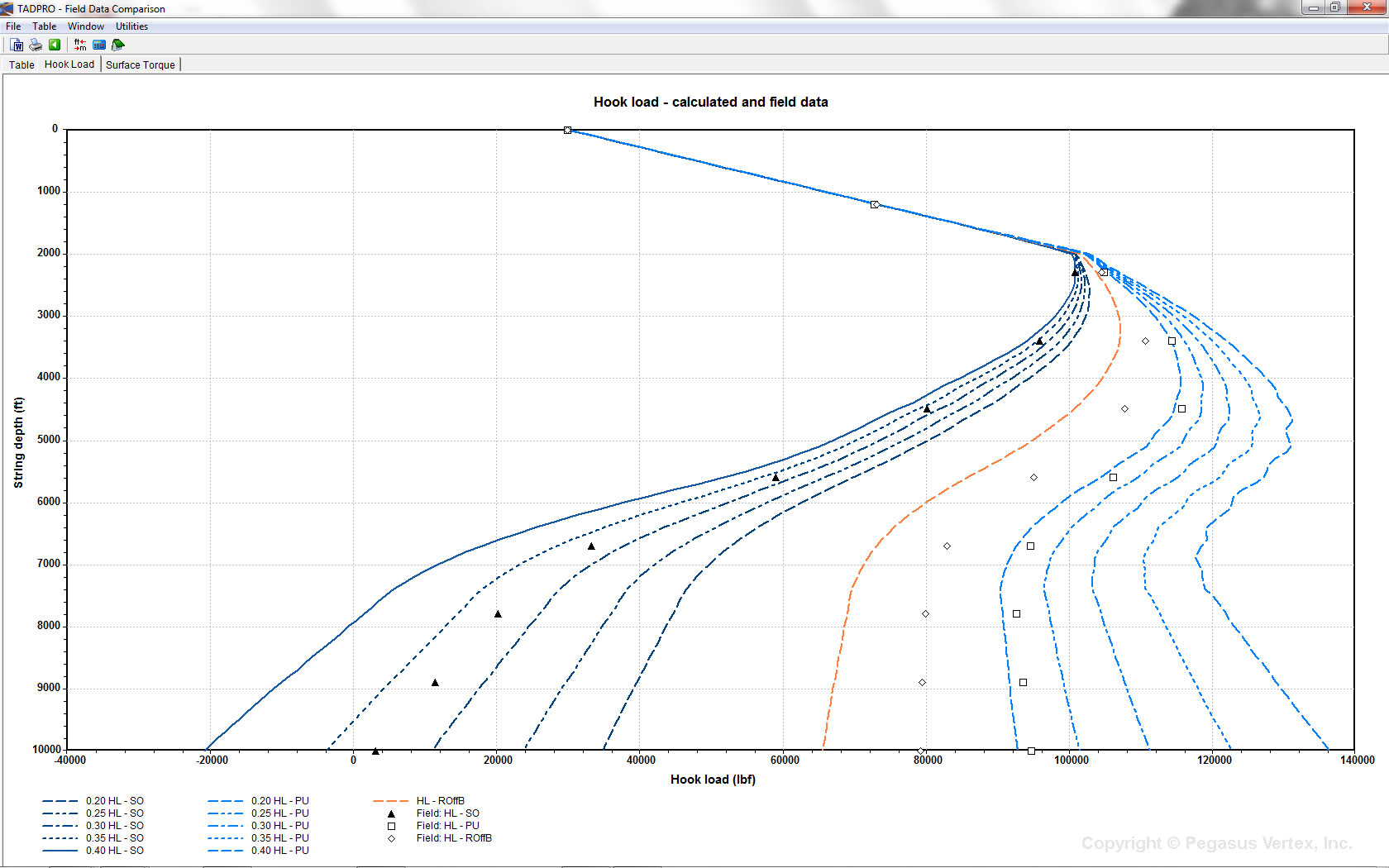

PVI’s torque and drag model, TADPRO, is designed to help remove many of the risks of a drilling program, completions design or specific tool operations. Limits in the length of a horizontal based on specific friction factors can be determined. It can evaluate the needed weight to a liner-top packer. TADPRO can analyze forces downhole and predict rig equipment specifications for torque and hookload. The model provides both versatility and accuracy in its calculations and it integrates advanced features that make it easier for our users to use.