There is a joke about the human brain and it goes like this: our brain has two parts. One is the left brain and the other is in the right. The right one has nothing left and the left one has nothing right.

According to the theory of left-brain or right-brain dominance, a person who is “left-brained” is often said to be more logical, analytical, and objective, while a person who is” right-brained” is said to be more intuitive, thoughtful, and subjective.

Artists may use the right side of their brains more to maximize creativity, but if they exhaust their imagination, their art works lose their appeal.

Sometimes, we, as viewers, participate in the creative process when we enjoy a good piece of art. This can be demonstrated in our appreciation of the statue of Venus de Milo. The statue is widely renowned for the mystery of her missing arms. The missing arms do not stop people from appreciating this marvelous work of ancient Greek. People are fascinated by the missing parts and are creating their own interpretations of the possible positions of the missing arms. By imagination, everyone creates a Venus statue in their mind. Maybe that is the everlasting beauty of Venus: the incompleteness of an original work of art.

However, in the world of engineering, we strive to remove any uncertainties as much as possible. Drilling software is a tool for drilling engineers to help them predict what will happen on the rig floor and downhole.

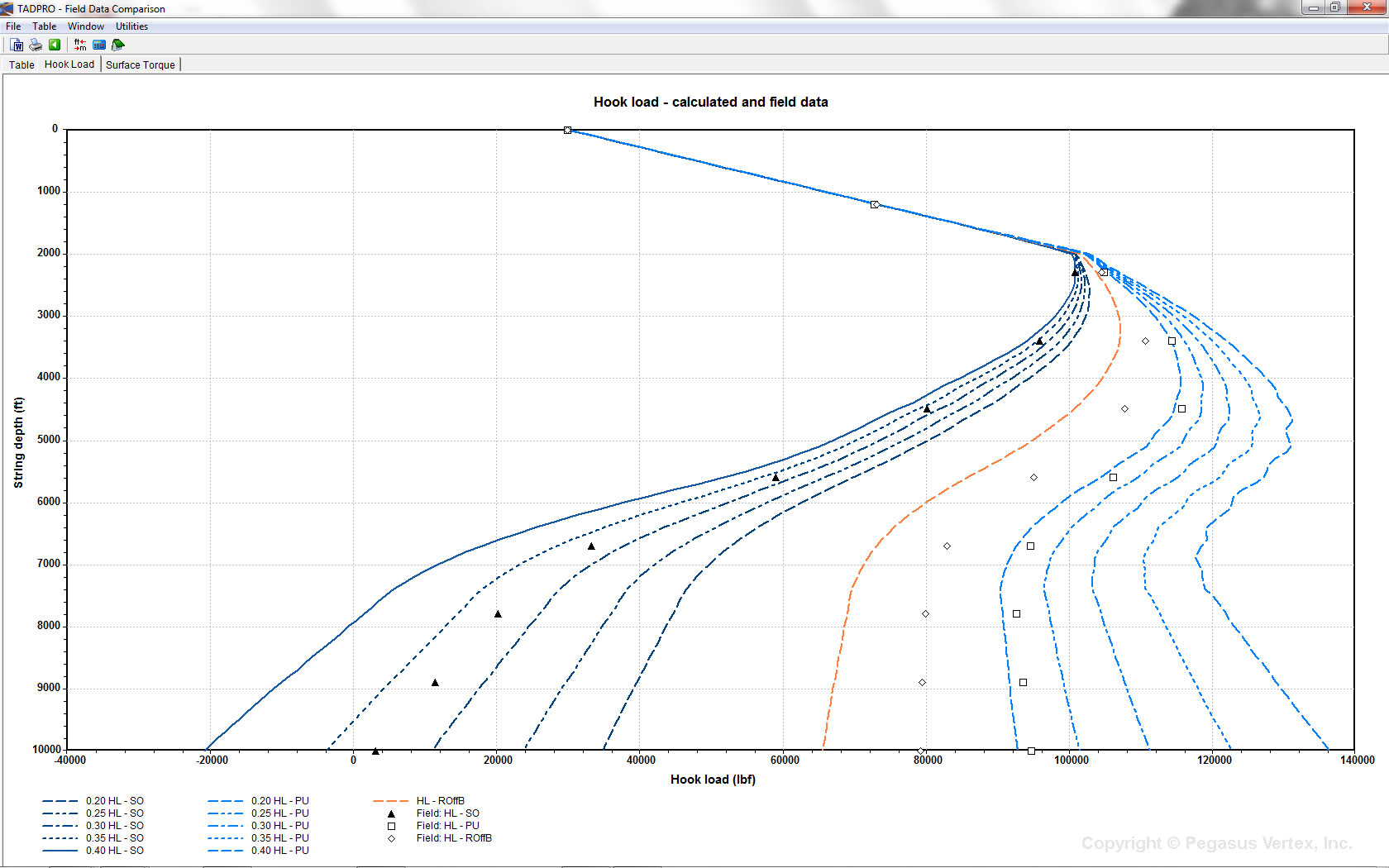

The following graph shows the hook load prediction using TADPRO (torque and drag model).

Charts like these give drilling engineers guidelines as to what to expect during drilling operations. This way, we can see the upcoming reality with little imagination.