Many of us wouldn’t go to see a doctor until we get sick. This not only costs more money, but also causes more pain. Preventive medical assessments may be seemingly unnecessary and unpleasant, but it can help identify potential health problems, save lives, and reduce medical costs.

We often hear of some famous physical doctors or medical experts, who have remedied illness, when troubles surfaced. As a matter of fact, we are all doctors ourselves, in a sense that we take care of our daily lives, command our bodies to certain tasks, and avoid certain activities. We, as doctors ourselves, play a big role every day in maintaining our health. We are all CEOs of our own way of life and happiness. If we do our best to keep up good habits, take care of our bodies regularly, we will save ourselves lots of trouble and money in medical expenses.

Prevention can be beneficial to drilling engineering as well. Our experiences gained and lessons learned help us make right decisions for our next well. Drilling engineering software also serves as a great tool to identify any potential problems in our existing drilling plan or make sound engineering designs.

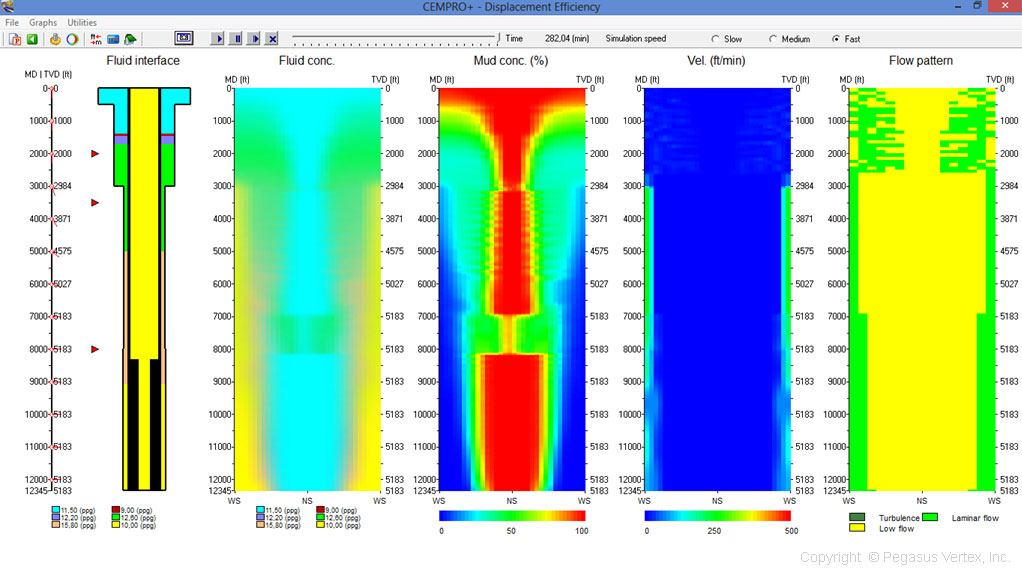

Take an example of cementing job design. One of the key elements of a successful cementing job is good displacement efficiency (less mud channeling). We have known that several parameters such as casing standoff, flow rate, differentials of fluid properties and hole deviation affect the effectiveness of fluid displacement. Now, with the help of computer modeling, we can see the impacts of these parameters. The following picture shows the mud concentration in the annulus at the end of the cementing job, where casing standoff is 0% throughout the wellbore (casting touches the borehole).

You can see that there are quite large red areas in track 3, indicating poor displacement efficiency.

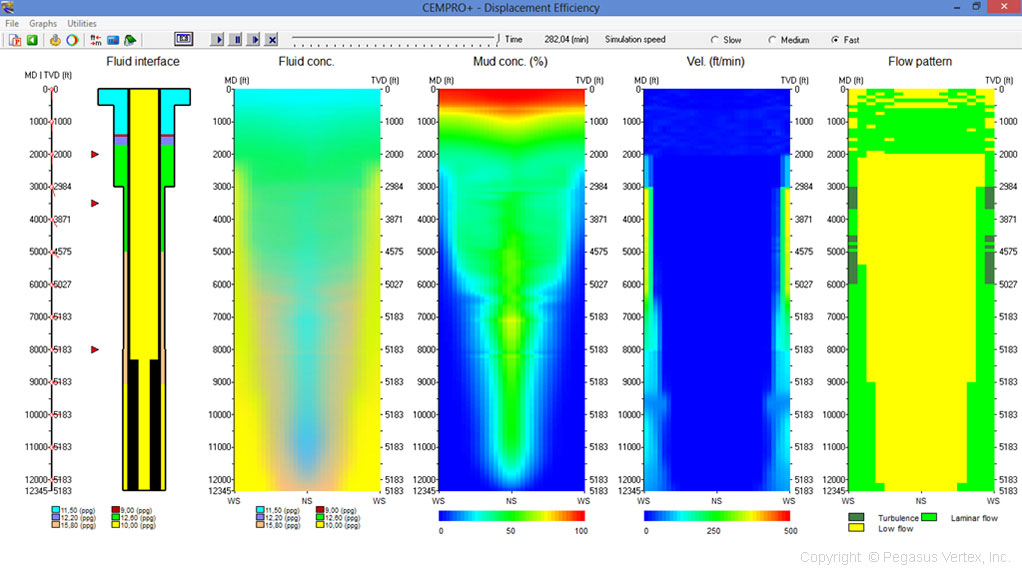

Now, we change the casing standoff to 70% and keep the other parameters the same. The following picture shows the much improved mud concentration after displacement:

Time and money (not to mention headaches) could be saved if drilling engineers undergo through all the engineering assessments before problems arise. Be sure to use your know-how, skills, experiences, lessons and available drilling software. Having a complete understanding of what will happen gives you a greater sense of control, reduces risks and saves money.