“Many people are confused with complexity and shy off from it. Strangely, complexity arises from simple rules, but people are finding it difficult to grasp. However, you need to move out of this situation soon before it gets out of control. Do what ants do: they diverge to look for new sources of food and then converge once a new path has been identified. Look for new ideas till you identify a new path or a new pattern to help you find the right key for the right lock that opens up the right door.”

As the 21st century passes, the oil industry continues to look for new ways to innovate and increase its productions. It continues to search for reserves in more complex environments, especially in deep water. Already many fields are slated for development in both shallow and deep offshore wells and new solutions and technology are needed to meet these goals.

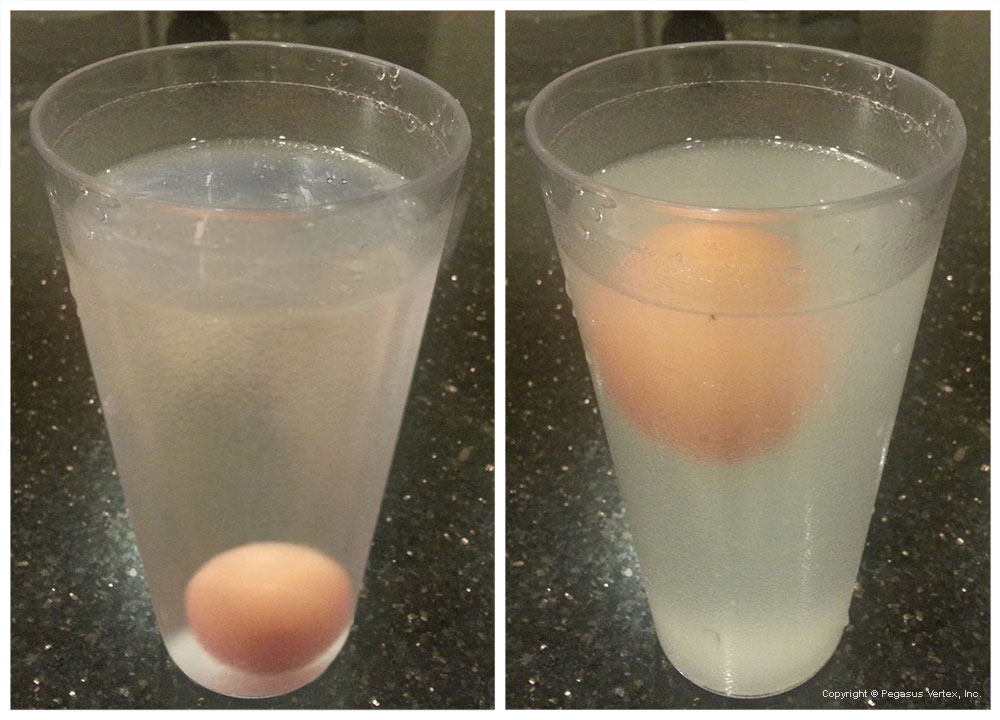

As a reservoir depletes, the pressure and production rates decline and lost circulation or differential sticking problems can prevent the drilling operations from increasing their production. Underbalanced drilling (UBD) is a practical method to drill in such depleted or low-pressure areas. One of the many benefits of underbalanced drilling is that it can prevent or reduce near wellbore permeability damage; as a result, it enhances the production, delaying water, gas or oil leaks due to the lower pressure drop that is required for the same flow rates.

- Improves drilling performance

- Increases penetration rate (ROP)

- Extends bit life

- Minimizes differential sticking of pipe

- Diminishes lost circulation

- Reduces formation damage

- Simplifies early production while drilling

- Allows formation evaluation and tests while drilling

- Higher productivity completions

- Picks total depth (TD) from inflow performance

- Closed, pressure-controlled system

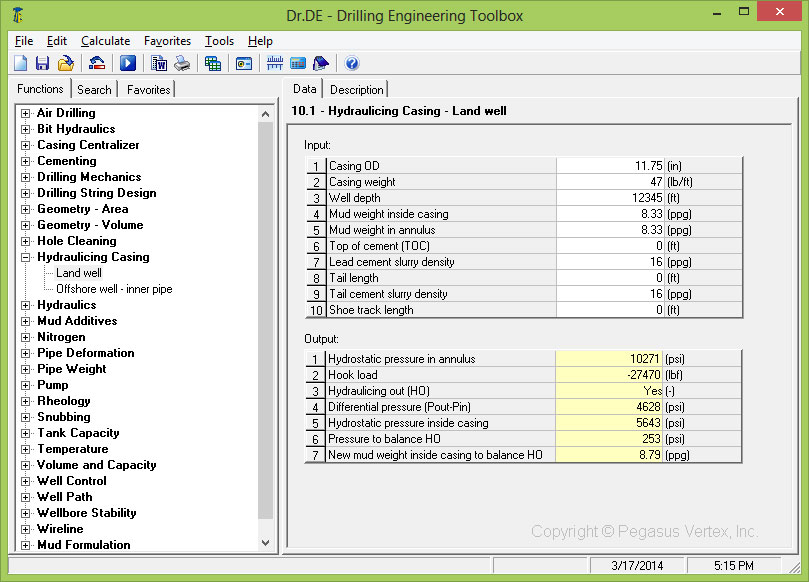

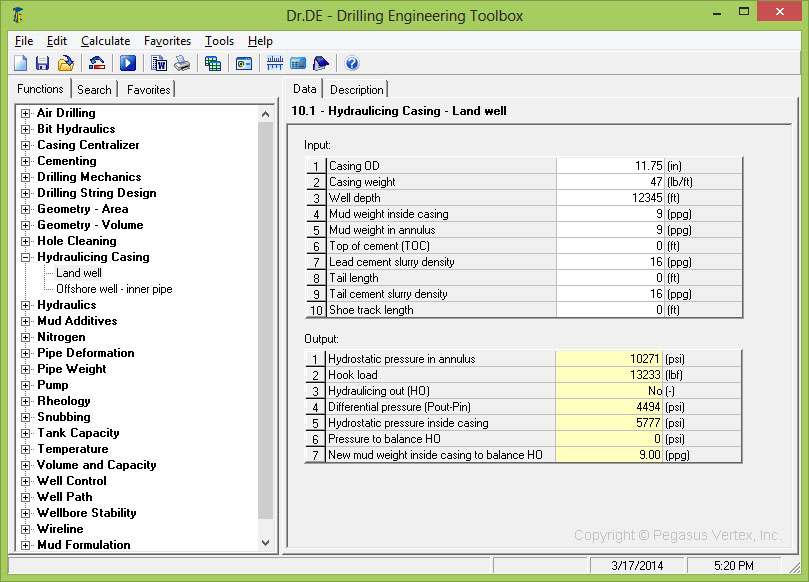

In order to design and achieve a successful underbalanced drilling project many important elements must be taken in consideration and there are 4 steps that have to be applied to determine the options and requirements for UBD: This is particularly important for underbalanced drilling operations offshore from floating vessels, where critical issues can increase significantly.

- Determine Bottom Hole Pressure (BHP) requirements.

- Identify the drilling fluid options.

- Establish the well design and perform flowing modeling.

- Select the surface equipment.

An advance software model has been developed which incorporates these elements, including multiphase flow calculations, gas and liquid injection rate optimization, hydrostatic gradient and frictional pressure loss calculations, cuttings transport, reservoir fluid influx (oil, gas, or water), and operational procedures such as tripping and liquid unloading.

Just like the rest of PVI's software, UBDPRO is the right tool when it comes to increasing a well’s productivity. It’s all about looking in the right direction (for the right key) and making the efforts to obtain it.