Drilling mud is used to assist the drilling of wellbore into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, mud is also used for much simpler wellbores. For instance, water wells. The three main categories of drilling fluids are water-based mud, oil-based mud, and synthetic mud. The main functions of the drilling mud include providing hydrostatic pressure to prevent formation fluids from entering into the borehole, keeping the drill bit cool and clean during drilling, carrying out drill cuttings, suspending the drill cuttings while drilling is paused, and when the drilling assembly is brought in and out of the borehole. The mud that is used for a particular job is selected to avoid formation damage and to limit corrosion.

On a drilling rig, mud is pumped from the mud pits through the drill string where it comes out of the nozzles on the drill bit, cleaning and cooling the drill bit in the process. The mud then carries the crushed or cut rock (better known as cuttings) up the annulus between the drill string and the sides of the hole

The drilling fluids carry the cuttings excavated by the drill bit up to the surface. The ability to do so depends on the cutting size, shape, density, and speed of the fluid traveling up the borehole, which is also known as annular velocity. The mud viscosity is another important property, as cuttings will settle to the bottom of the well if the viscosity is too low. Fluids that have shear thinning and elevated viscosities are efficient for wellbore cleaning. High density fluids may clean the hole adequately even with lower annular velocities, but may have a negative impact if mud weight is in excess of that needed to balance the formation pressure. For this reason, mud weight is not usually increased for hole cleaning purposes.

Mud density should be limited to the minimum necessary for well control and wellbore stability. If too great, it may fracture the formation. Depending on the mud system in use, a number of additives can improve the filter cake and therefore maintain the wellbore stability.

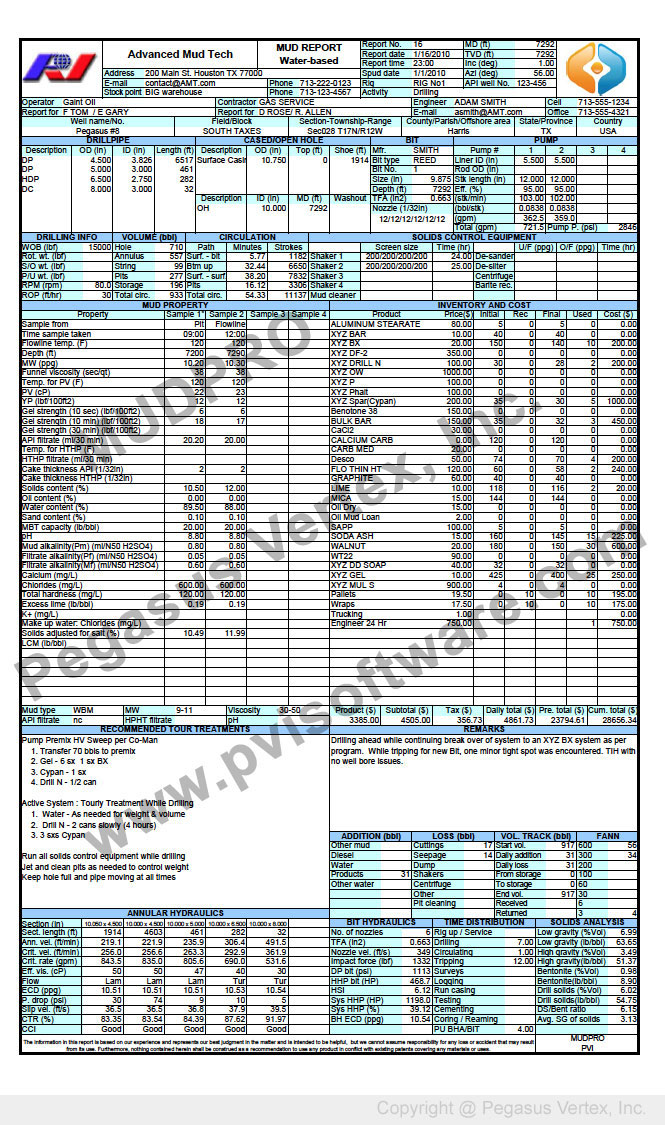

As we can see, mud is a vital part of drilling operations. How can mud be managed in such a way to have success in these operations? This type of mud contains carefully chosen additives to control its properties. It is the responsibility of the mud engineer to ensure that any new mud that is produced and added, meets the required specifications.

In the past, mud engineers used paper forms or Excel® spreadsheets to record mud properties, product usage, and inventory every morning. With these methods, engineers encountered problems such as disorganization of numerous daily reports and difficulty in generating end-of well recaps.

MUDPRO is a mud reporting software developed by PVI that complies with API specifications for field use.

With a backbone of databases, this all-inclusive model highly improves data gathering, sharing and management. MUDPRO is designed for mud engineers at the rig sites as well as the company men in the office. A mud engineer can use it to record mud data and generate daily reports. It can also be used by company men for reviewing and managing data, making an end-of-well recap, and comparing data between multiple wells.

With a backbone of databases, this all-inclusive model highly improves data gathering, sharing and management. MUDPRO is designed for mud engineers at the rig sites as well as the company men in the office. A mud engineer can use it to record mud data and generate daily reports. It can also be used by company men for reviewing and managing data, making an end-of-well recap, and comparing data between multiple wells.