I visited Venice after this year’s SPE/IADC Conference in Amsterdam in March. During that week in Venice, I stayed in a quiet world: no automobile, no motor cycle or train. You can simply add “water” in front of the names of our ordinary transportation to describe the local means of moving around: water-bus, water-taxi, and water-gondola.

While enjoying the Italian cuisine and limoncello, I suddenly thought of one of the famous play of Shakespeare’s: Merchant of Venice. The story with Venice as the venue goes like this.

A Venetian merchant Antonio has a friend Bassanio, who is desperately in need of money to court Portia, a wealthy heiress who lives in another city. Without enough money, Bassanio and Antonio finally secure the loan from Shylock, a Jewish moneylender, with Antonio as the loan’s guarantor. Shylock hates Antonio, but acts agreeably and offers to lend Bassanio three thousand ducats with no interest. Shylock adds, however, that should the loan go unpaid, shylock will be entitled to a pound of Antonio’s own flesh, to which Antonio agrees.

Later in story, news comes that Antonio has lost his ships, and that he has forfeited his bond to shylock. Shylock ignores the many pleas to spare Antonio’s life, and a trial is called to decide the matter. Portia, his friend’s fiancée, disguises as a young man of law and asks Shylock to show mercy, but he remains inflexible and insists the pound of flesh is rightfully his. Portia examines the contract and, finding it legally binding, declaring that Shylock is entitled to the merchant’s flesh. Shylock ecstatically praises her wisdom, but as he is on the verge of collecting his due, Portia reminds him that he must do so without causing Antonio to bleed, as the contract does not entitled him to any blood. Trapped by this logic, Shylock hastily agrees to take Bassanio’s money instead. The ending of the story has more drama.

We live in a world of measurements. Measurement is a cornerstone of engineering and science. For some reason, the story in my memory is that Portia reminds Shylock that he has to cut exactly one pound of Antonio’s flesh, not even one ounce more or less.

In drilling industry, we have mud weight (ppg) to measure the density of drilling fluid, pipe weight(lb/ft) to represent the thickness of pipe with given OD. The weight indicator - hook load is the total force acting (pulling down) on the hook on the rig.

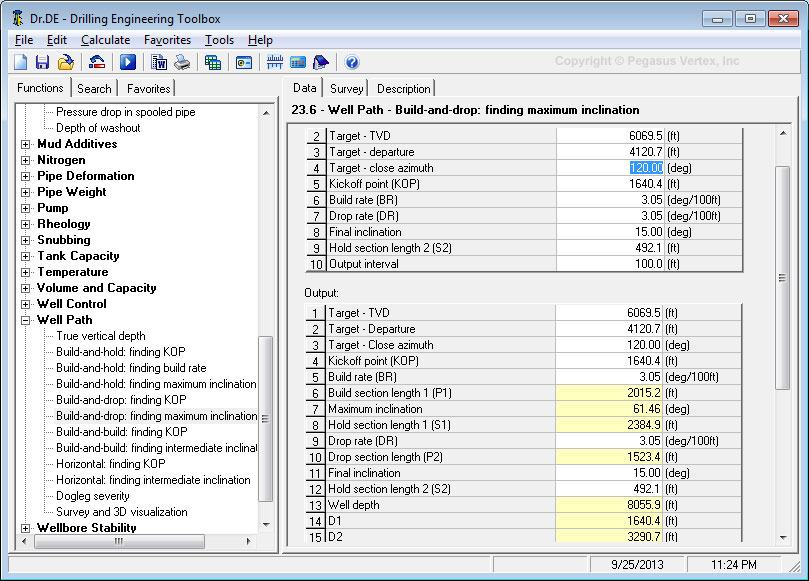

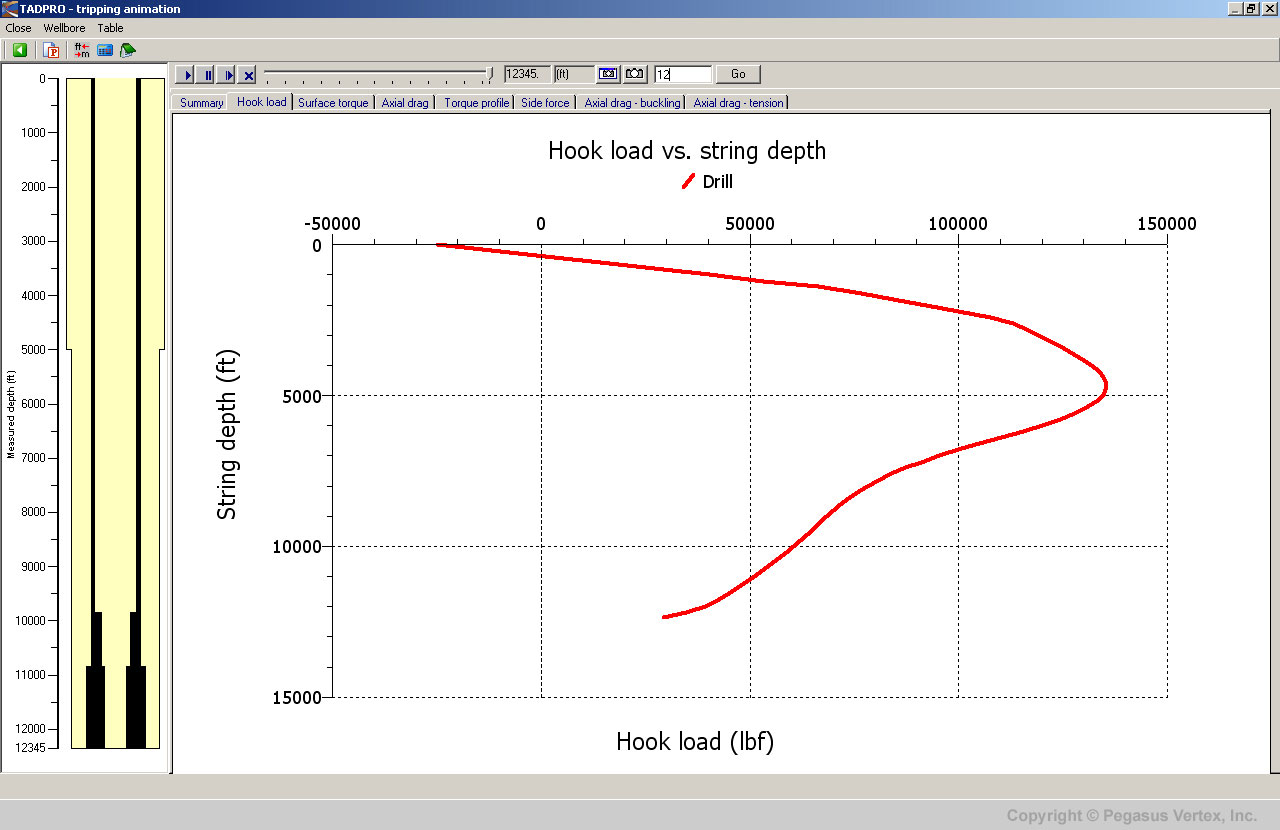

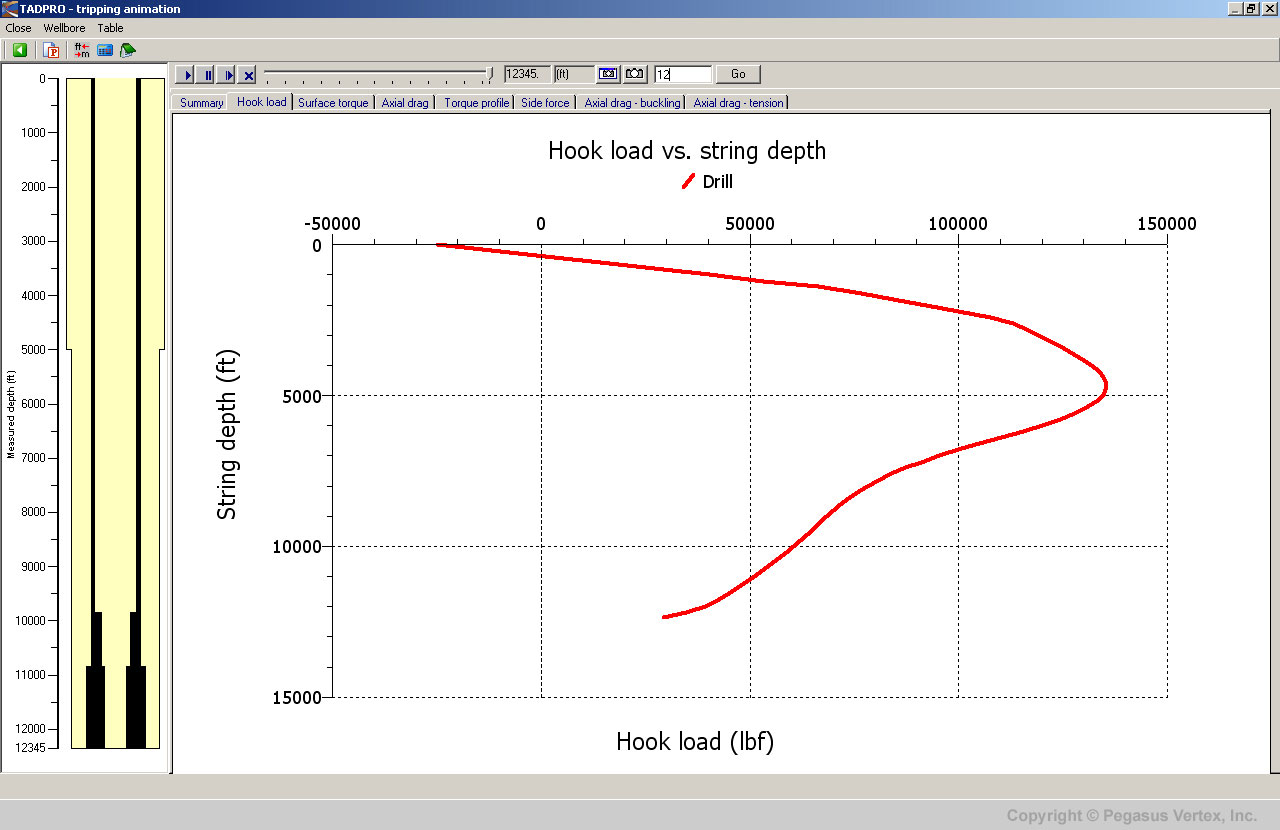

Hook load is one of the few important readable operation parameters on rig floor. It’s basically the total force includes those of traveling assembly weight, buoyant pipe weight in a deviated well plus or minus the frictional drag caused by pipe movements inside borehole. Torque and drag (T&D) software such as TADPRO serves the purpose of predicting hook load, surface torque and other variables for drilling and tripping operations.

We can calculate hook load and surface torque precisely if we know all the details downhole. However, the uncertainties downhole, such as open hole sites, survey accuracy, make the prediction exactly match rig floor reading unlikely. This does not discount the importance of hookload prediction, because the significance of T&D calculation is its trend.

The following picture shows the hook load changes as we drill to TD. The hook load is increasing at beginning (due to longer pipe into the hole) and decrease later as we drill into build-up and horizontal sections (more drag).

Hook Load Predicted by TADPRO

Eventually, the hook load is approaching zero. This indicates that the pipe weight in the vertical section will not be enough to overcome the frictional drag resulted from the horizontal section: a problem associated with horizontal and extend-reach well drilling.

A pound more or less on this curve is not as important as the trend, which signals us what will happen according to our planning.