Dr. DE - A Simple Way to Solve Complex Drilling Problems

Check this white paper to learn more on how Dr. DE allows you to quickly and accurately perform many daily used drilling engineering calculations. It covers more than 190 functions ranging from the fundamentals of drilling engineering to an advanced well path design and 3D visualization of the wellbore.

I. Problem

The past century has seen many advances in drilling technology. Literatures, books, computer programs and various other sources have been put together by the brightest minds of drilling professionals.

While the technological know-how has tremendously driven the industry forward, individuals are sometimes overwhelmed by the vast amount of information they receive from different sources of media.

Figure 1: Knowledge is Power

Figure 1: Knowledge is Power

Knowledge is power only when you have access to it in a timely fashion. The internet is loaded with data, but this data needs to be validated. Different pieces of information are scattered around in engineering textbooks, SPE series, IADC manuals, etc. Almost every engineer has their own Excel Spreadsheets, which may generate different answers.

Drilling software can predict the torque and drag for deepwater ERD wells, but may not answer the simple question of the buoyancy factor.

The challenge is to create an all-in-one type of information and knowledge base program. A digital toolbox that bears the following characteristics:

• Quick to access

• Reliable

• Accurate

• Interactive

• Visually intuitive

• Sophisticate yet simple to use

II. Solution

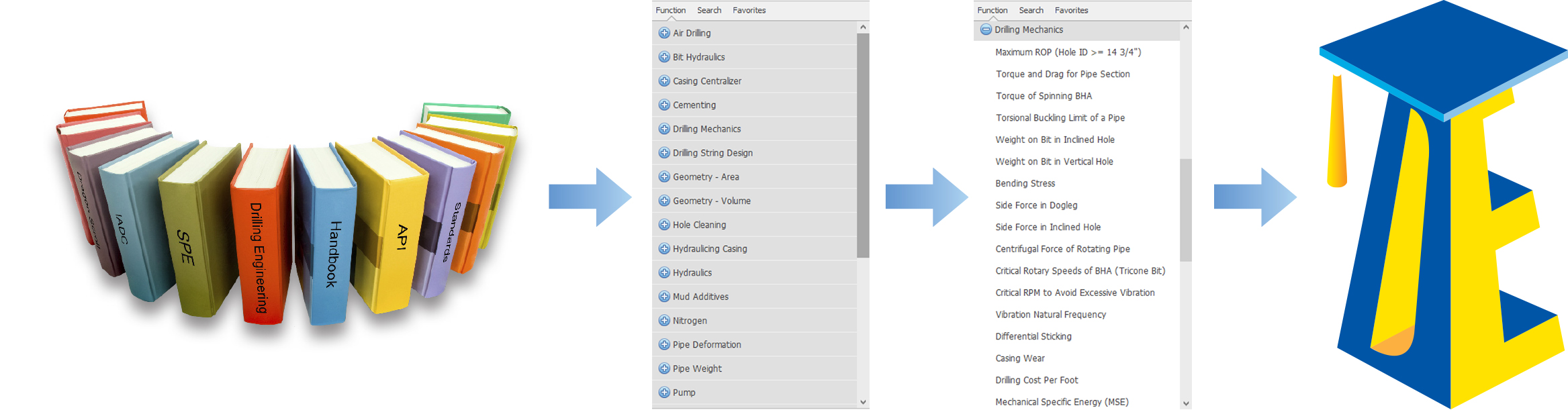

Now much of the technological advances and engineering applications from four decades of hard work have been distilled into Dr. DE, a comprehensive collection of drilling engineering tools in a simple-to-learn and easy-to-use software package.

Figure 2: Distillation

Figure 2: Distillation

You can bid farewell to pawing through handbooks and Excel spreadsheets for answers, because Dr. DE covers more than 190 functions ranging from the fundamentals of drilling engineering to an advanced well path design and 3D visualization of the wellbore – a must-have resource for every drilling engineer and technician to get the job done right.

With an unmatched number of functions and accuracy, Dr. DE allows you to quickly and accurately perform many daily used engineering calculations. It makes your engineering and sales efforts easier and more efficient.

Some of Dr. DE’s engineering features include:

• Daily used drilling engineering problems and solutions

• Extensive and expandable tubular, centralizer and fluid database

• Survey data up to 1,000 points

• 3D wellbore visualization

• Intelligent 2D well path design

• Detailed illustrations

• Support fraction input of tubular sizes, e.g. 9 7/8”

• Search function and Favorite list

• Word, Excel, PDF, and HTML reportsUS oil field, metric and customized units

Please see Appendix A for the list of 26 groups and 193 functions in Dr. DE.

III. Software

1. Graphical User Interfaces

Dr. DE is designed with our frequent users in mind. Interfaces and input and output tables are arranged in such a way that the software can be run without users going through training or reading the user’s manual.

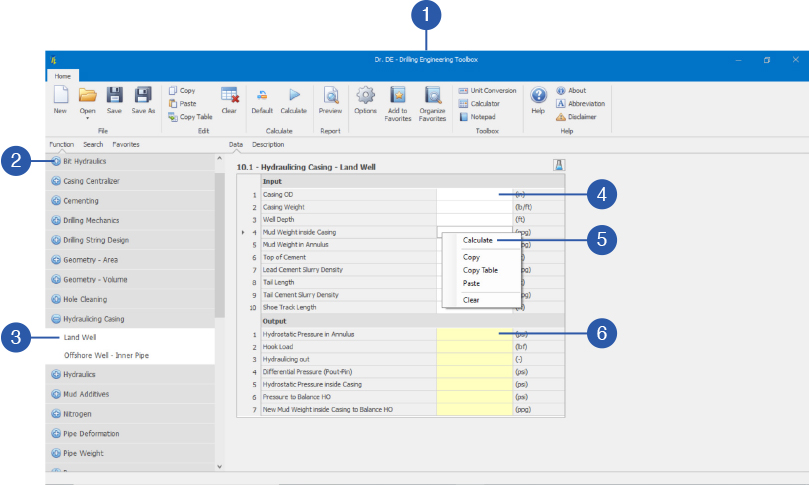

Figure 3 shows the components of the main window for Dr. DE.

Figure 3: Components of the Main Window

Figure 3: Components of the Main Window

Some of Dr. DE’s engineering features include:

(1) Toolbar contains frequently used commands

(2) Groups include various numbers of functions

(3) Function is to perform a particular calculation

(4) Input data for the function selected

(5) Pop-up menu allows the user to start calculation

(6) Output data calculated from the input data

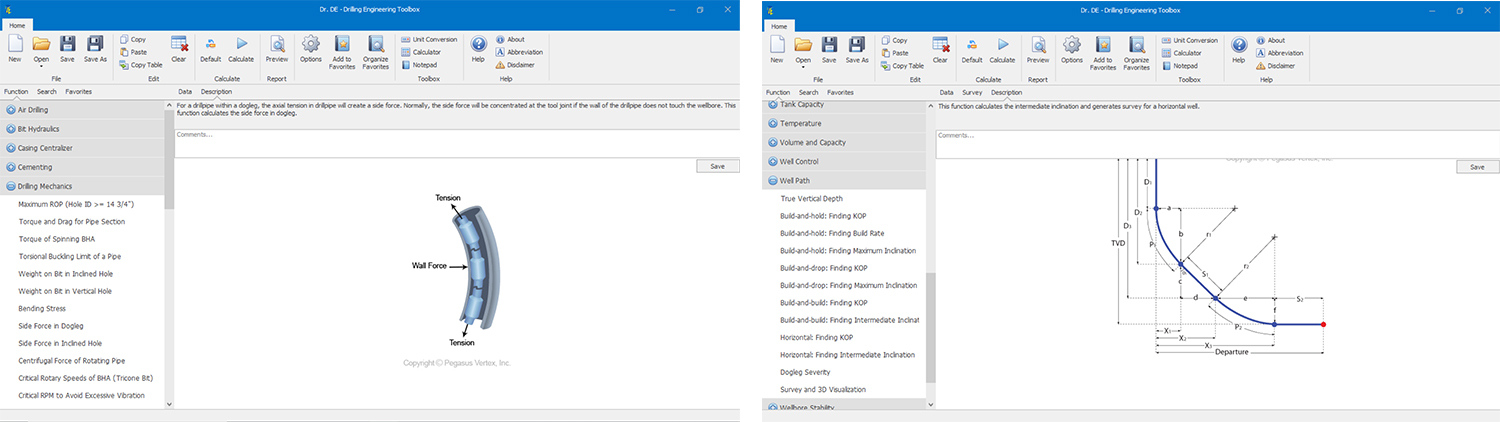

Dr. DE is equipped with many illustrations related to particular functions. These illustrations help users to understand the problems and calculated parameters.

Figure 4: Illustrations

Figure 4: Illustrations

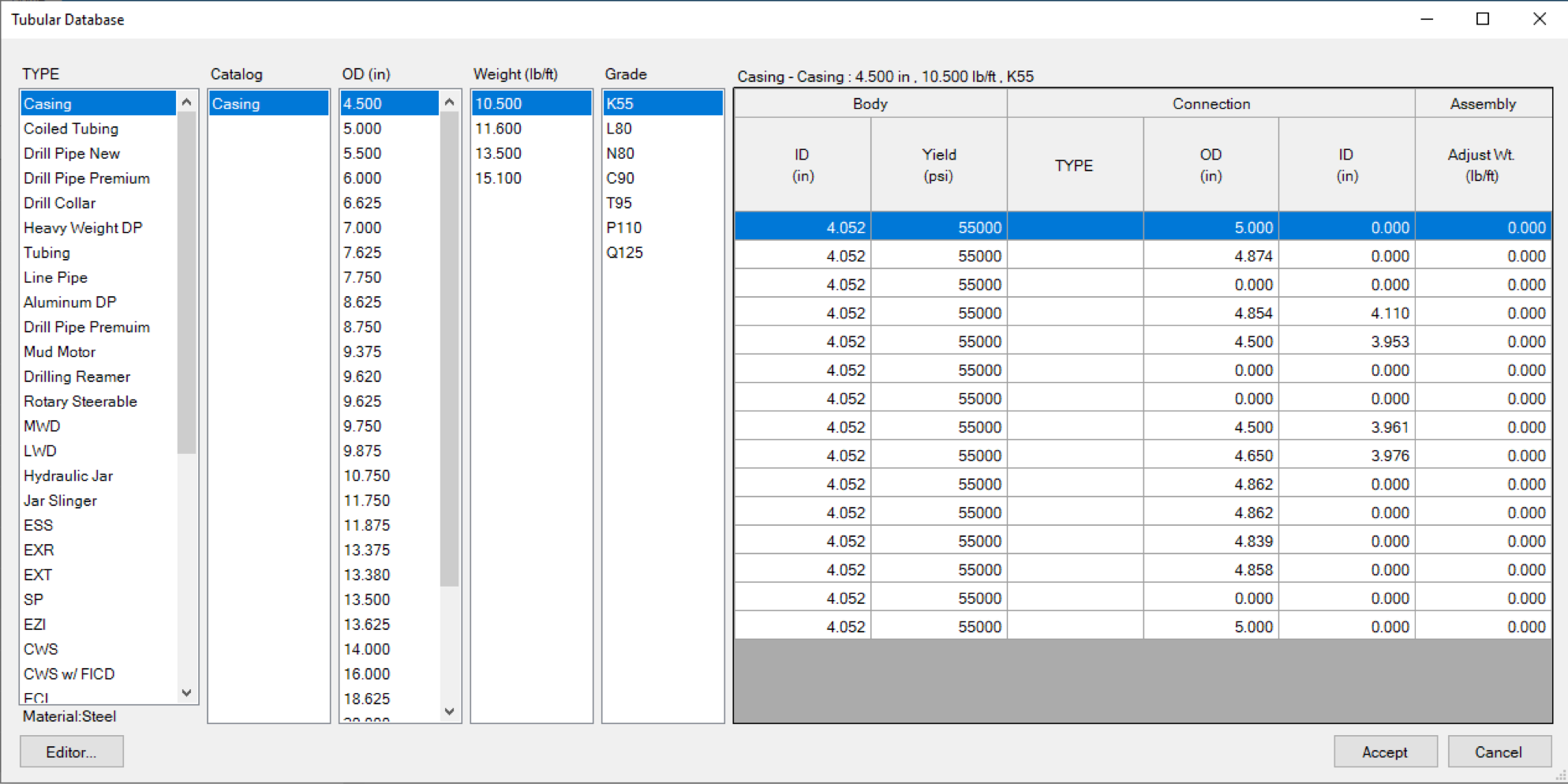

2. Tubular Database

Dr. DE provides extensive tubular and centralizer databases complemented by a fluid database.

Many functions in Dr. DE require the input of pipe OD, weight and ID, etc. You can input them into the table directly. Alternatively, you can click the button on the upper right corner of the input table to open the Tubular Database window.

Figure 5: Tubular Database

Figure 5: Tubular Database

Dr. DE allows the users to input them in fraction format. The fraction format is as follows: an integer + “ “ + a fraction, e.g. 9 7/8. Once the user hits the Enter key, the program converts the fraction format to decimal format. (e.g. 9 7/8 to 9.875).

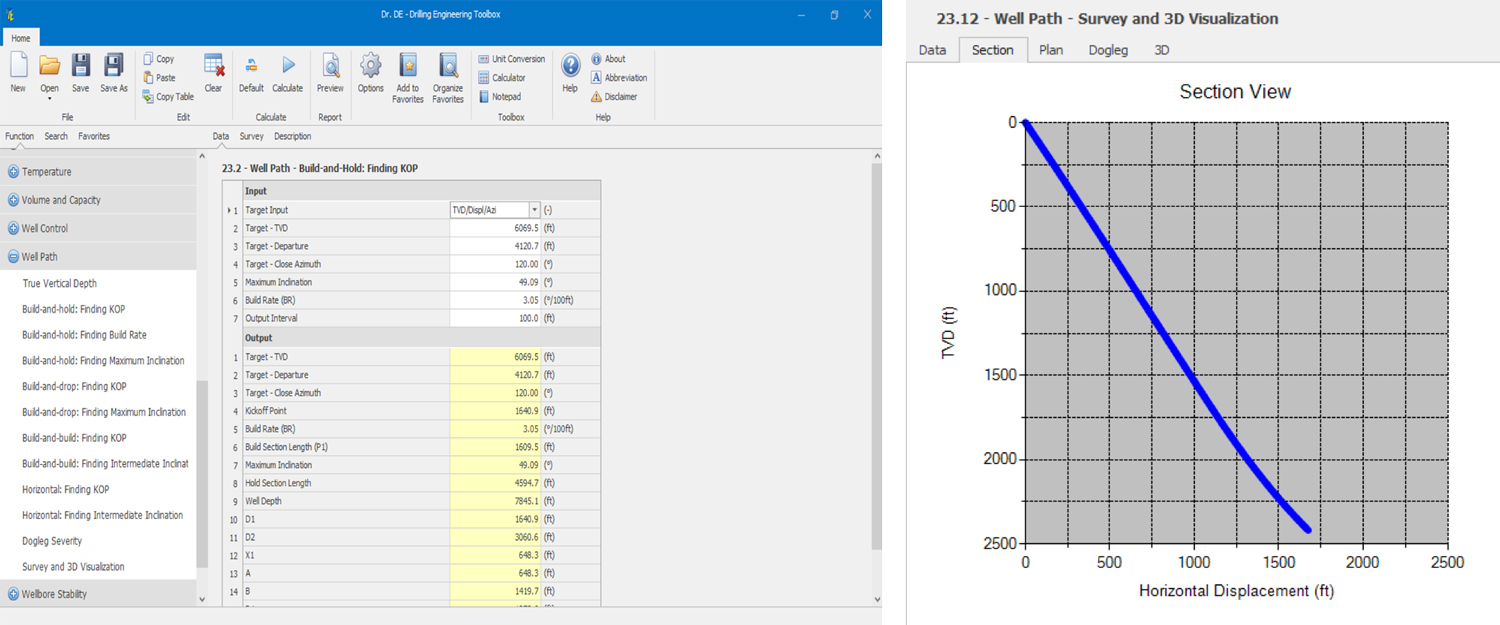

3. Well Path Design

For a well path design, there are many input parameters involved as well as a myriad of different combinations. Sometimes the situation may lead to where a valid well path is impossible. Traditionally, the trial and error method can be utilized to obtain the desired design. Dr. DE has an advanced well path design feature called the Well Path Intelligent System. Dr. DE will check the values of the data already inputted and provide a range of the current data in order to create a meaningful well path. The Well Path Intelligent System will save you a tremendous amount of time and effort in complicated 2D well designs.

Well Path Group in Dr. DE includes nine 2D well path design functions.

| Well Type | Parameter to be Determined |

| Build-and-Hold | • Kick off Point (KOP) • Build Rate • Maximum Inclination |

| Build-and-Drop | • Kick off Point (KOP) • Maximum Inclination |

| Build-and-Build | • Kick off Point (KOP) • Intermediate Inclination |

| Horizontal | • Kick off Point (KOP) • Intermediate Inclination |

Figure 6: Well Path Design

Figure 6: Well Path Design

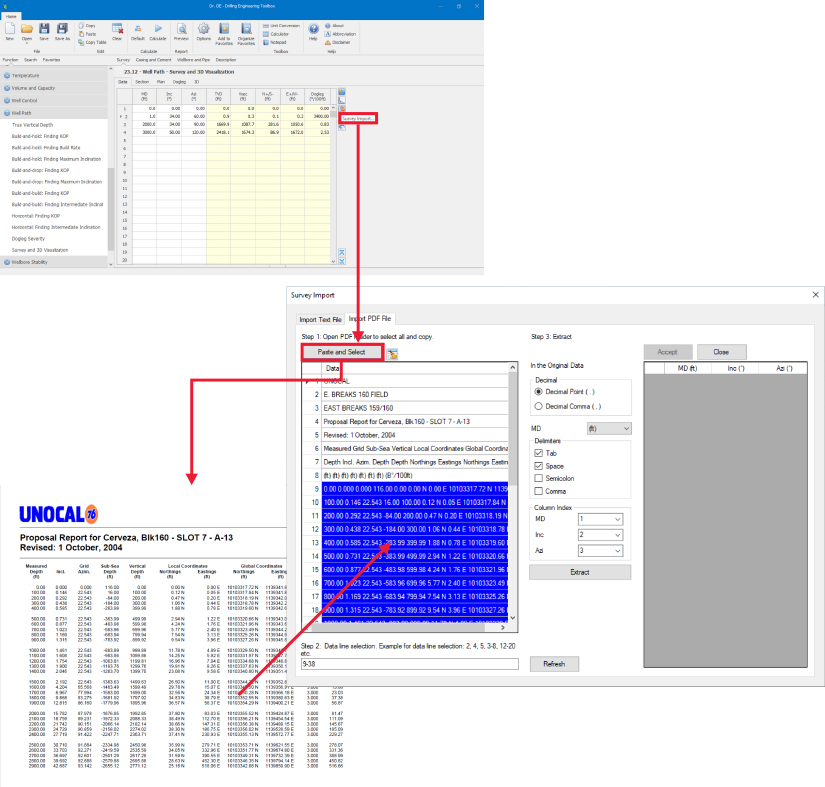

4. Survey Import

Survey data can be directly inputted, copied and pasted, imported from text files or even PDF files.

Figure 7: Survey Import

Figure 7: Survey Import

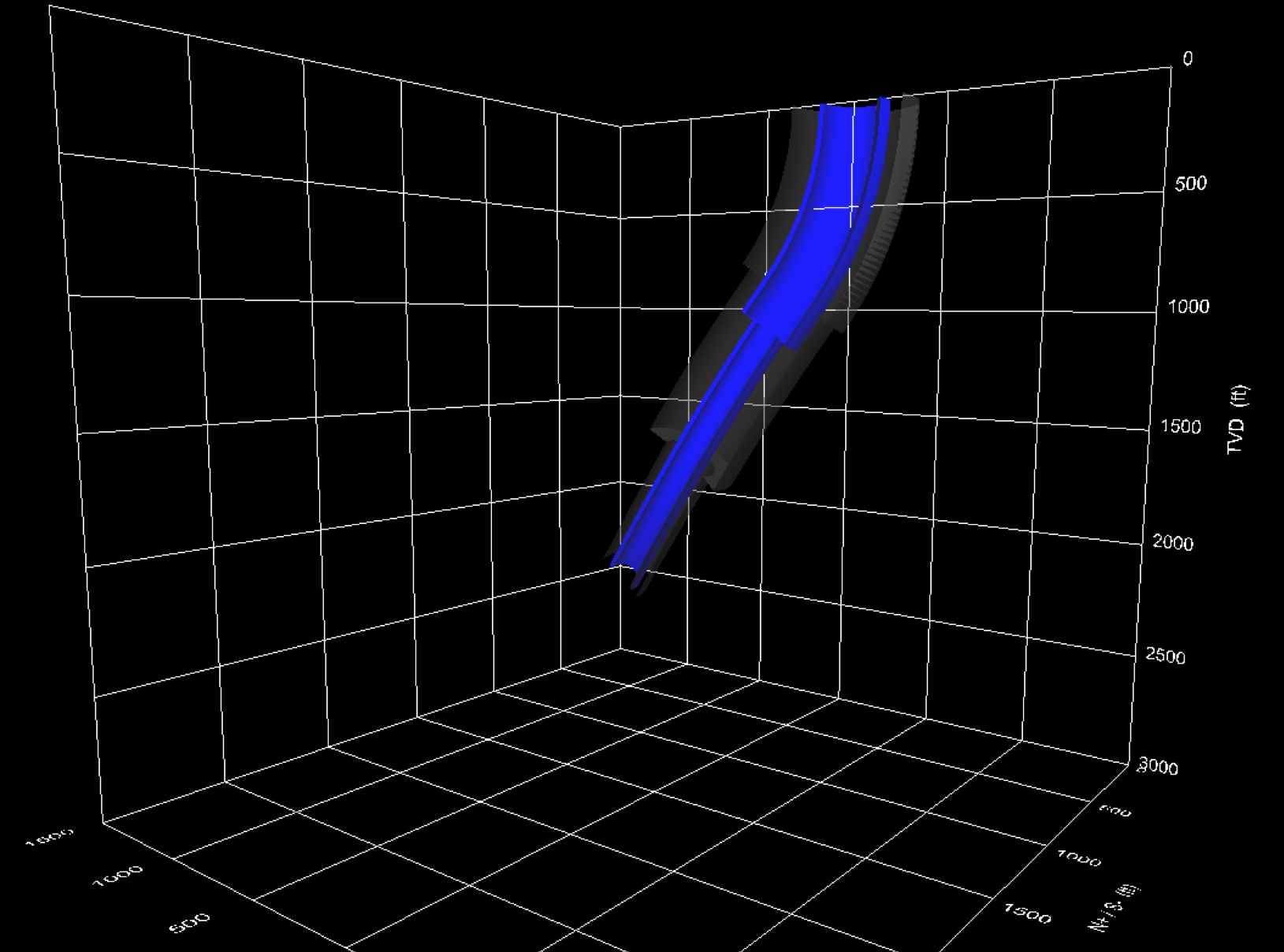

5. 3D Visualization

With the survey data entered or generated by well path design functions, Dr. DE can create a 3D well path visualization with a few clicks. 3D well visualization includes:

(1) Well path

(2) Casing and cement (wellbore structure)

(3) Wellbore and pipe

Figure 8: 3D Wellbore Structure

Figure 8: 3D Wellbore Structure

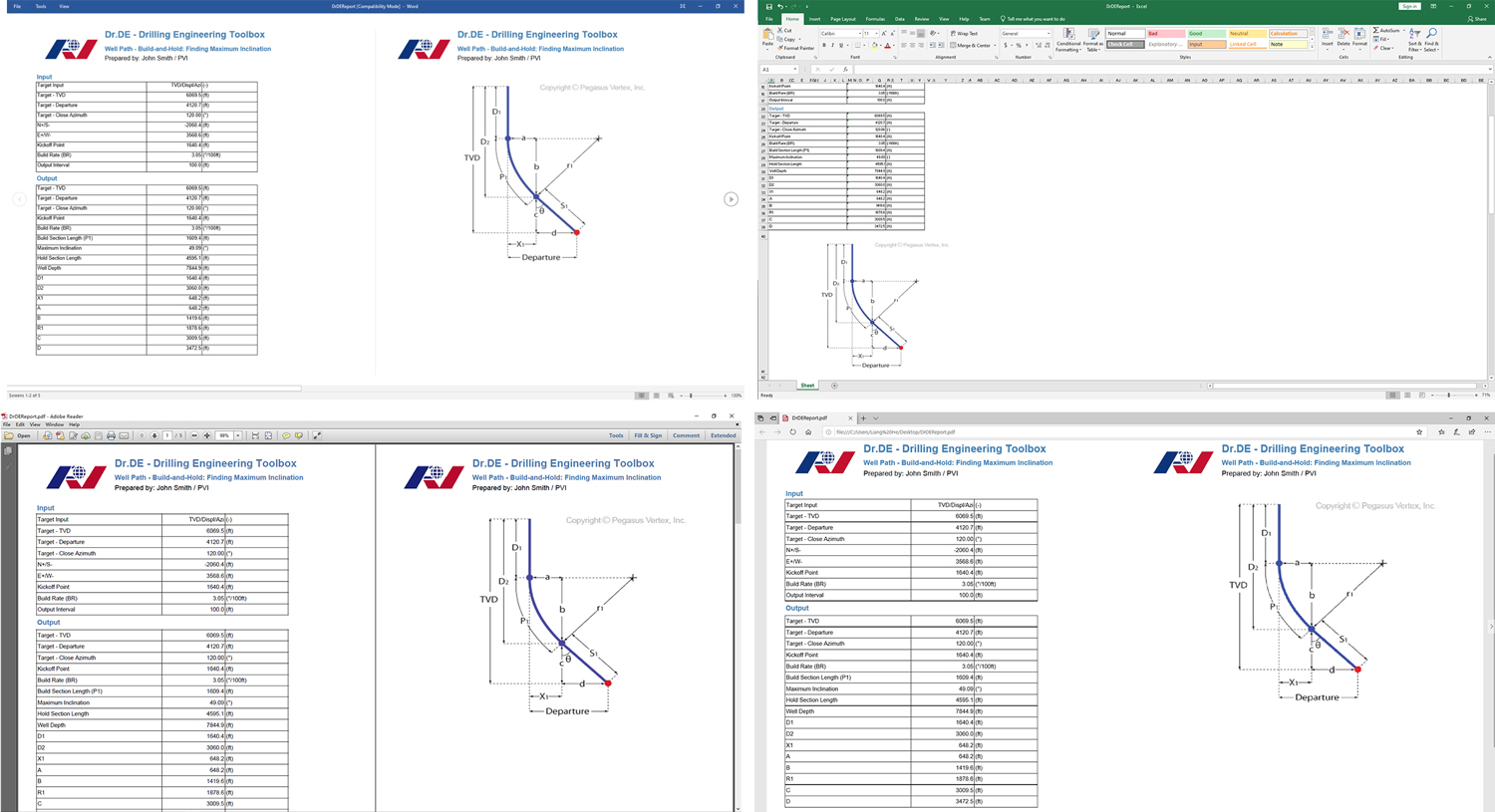

6. Reports

Dr. DE provides the following methods for output results: Copy and Paste, Word, Excel, Power Point and HTML Report.

Figure 9: Reports

Figure 9: Reports

7. Search and Favorites

Due to the large number of functions and vast areas Dr. DE covers, you may feel overwhelmed and lost. Dr. DE provides simple solutions. Click the “Search” tab and type the keywords of your desired function. As you type, Dr. DE will dynamically provide a list of possible matches in the drop-down list below. When you finish typing, the search result list will display all possible matches. Clicking any of those matches will take you to the corresponding function.

Likewise, when you find groups or functions that you like, you can add the functions to your Favorites list. As your list of favorite functions grows, you can keep it organized by creating folders. You may want to organize your functions by topic.

Figure 10: Search and Favorites

Figure 10: Search and Favorites

This powerful toolbox software was built on rock-solid foundation of:

• PVI’s years of drilling engineering and software experiences

• Best elements from PVI’s existing software

• 100+ technical references and resources

• Careful scrutinizing, compiling and verification

• Rigorous and extensive testing

Think of Dr. DE as an assistant with a doctorate degree, educated and trained to simplify and empower your drilling engineering process. With the incomparable collection of functions and intuitive access, solving drilling problems or pleasing the clients has never been so easy. Finally, when your clients or manager are ecstatic by the work you produce, Dr. DE would insist that you take all the credit.

IV. The Future

A successful software recognizes the need for future expansion to manage the increased complexity that comes with evolving technological solutions. We embrace the opportunities of adding your desired functions into Dr. DE.

2000 years ago, Chinese philosopher Lao Tsu said: “A journey of thousand miles begins with the first step.” We would like to invite you, our fellow drilling engineers and technicians, to start the journey with Dr. DE; you will never be alone.

For more than a decade, PVI has been committing to providing software solutions to the drilling community. Today, PVI is proudly setting a new industry standard for digital technical tools with the unveiling of Dr. DE, a comprehensive toolbox that goes beyond what has been seen in the current drilling software market.

V. Appendix A: 26 Groups and 187 Functions in Dr. DE

| Group Name | Function Name |

| Air Drilling | • Gas Expansion Equation • Required Gas Circulation Rate • Air Drilling Pump Pressure • Air Drilling Pressure Loss in Pipe |

| Bit Hydraulics | • Bit Size Selection • Nozzle Area • Bit Hydraulics • Bit Hydraulics Optimization |

| Casing Centralizer | • Standoff - Given Standoff • Standoff - Given Annular Clearance • Standoff of Rigid Centralizer • Equivalent Pipe OD • Casing Sag Between Centralizers |

| Cementing | • Cement Additive • Weighted Cement • Length to be Cemented • Sacks of Cement • Balanced Cement Plug • Fluid Volume • Open Hole Excess Estimation • Wiped Mud Film When Using only Top Plug |

| Drilling Mechanics | • Maximum Rop (Hole ID >= 14 ¾”) • Torque and Drag for Pipe Section • Torque of Spinning BHA • Torsional Buckling Limit of a Pipe • Weight on Bit In Inclined Hole • Weight on Bit In Vertical Hole • Bending Stress • Side Force in Dogleg • Side Force in Inclined Hole • Centrifugal Force of Rotating Pipe • Critical Rotary Speeds of BHA (Tricone Bit) • Critical RPM to Avoid Excessive Vibration • Vibration Natural Frequency • Differential Sticking • Casing Wear • Drilling Cost per Foot |

| Drilling String Design | • Mechanical Specific Energy (MSE) • Drillpipe Length for a Specified BHA • BHA Length for Desired WOB • Maximum Permissible Dogleg Severity • Pipe-wall Thickness Modification |

| Geometry - Area | • Annulus • Circle • Ellipse • Section of a Ring • Sector of a Circle • Segment of a Circle • Segment of an Annulus - 1 • Segment of an Annulus - 2 • Triangle • Rectangle • Parallelogram • Trapezoid |

| Geometry - Volume | • Hollow Cylinder • Hollow Sphere • Oblique Prism • Pyramid • Truncated Pyramid • Right Cone • Truncated Right Cone |

| Hole Cleaning | • Slip Velocity • Amount of Cuttings • Bulk Density of Cuttings • Carrying Capacity Index (CCI) • Cuttings Suspension • Contact Time in Annulus |

| Hydraulicing Casing | • Land Well • Offshore Well - Inner Pipe |

| Hydraulics | • Equivalent Circulating Density • Hydraulic Diameter • Mud Hydrostatic Pressure • Hydrostatic Pressure with Mixture of Oil and Water • Mud Weight Increase due to Fast Drilling • Pressure Drop (Bingham Plastic) - Pipe • Pressure Drop (Bingham Plastic) - Annulus • Pressure Drop (Power Law) - Pipe • Pressure Drop (Power Law) - Annulus • Annular Pressure Loss - Quick Estimate • Surface Equipment Pressure Loss • Annular Velocity - From Diameter • Annular Velocity - From Capacity • Hydraulic Horsepower • Hydraulic Impact Force • Loss of Overbalance due to Falling Mud Level • Loss of Overbalance due to Lost Returns • Hydrostatic Pressure Decrease When Pulling Pipe Out • Surge and Swab Pressure • Flow Split • Critical Static Gel Strength • Pressure Required to Initiate Flow • Pressure Drop in Spooled Pipe • Depth of Washout • Annular Shear Rate |

| Mud Additives | • Brine Density Change • Barite Density Control with Solids Dilution • Density of Oil/Water Mixture • Final Density and Volume • Number of Sacks Required • Oil/Water Ratio from Retort Data • Original Volume Required • Amount of Oil/Water Added • Original Volume Required with Limit Final Volume • Maximum Solid Fractions • Mud Density Control • Solids Control For Weighted Muds |

| Nitrogen | • Properties and Conversion Data For N2 • Amount of Nitrogen to Fill CT • Gas Density • Volume Factor • Foamed Cement - Given Foam Density • Foamed Cement - Given Foam Quality • Foamed Cement - Given Nitrogen Injection Ratio • Pressure and Density of Gas Column |

| Pipe Deformation | • Moment of Inertia • Moment of Inertia of a Rectangle • Stiffness • Pipe Elongation • Pipe Twist • Pipe Bending • Buckling Limits • Pressure, Tensile and Torsional Limits • Length of Free Pipe • Critical Length of Tool - Abrupt Dogleg • Critical Length of Tool - Circular Dogleg • Triaxial Stress (Von Mises Stress) |

| Pipe Weight | • Buoyancy Factor • Buoyed Weight in One Fluid • Buoyed Weight in Two Fluids • Pipe Id From Pipe OD and Weight • Pipe Weight From OD and ID |

| Pump | • Duplex • Triplex |

| Rheology | • Fann Viscometer Reading • Get N and K from PV and YP • Get PV and YP from N and K • PV, YP, N and K • PV and YP Estimation • Critical Annular Velocity and Flow Rate |

| Snubbing | • Pressure Area • Required Hydraulic Pressure • Pipe Buckling at The Surface |

| Thank Capacity | • Horizontal Cylindrical Tank with Flat Heads • Horizontal Cylindrical Tank • Vertical Cylindrical Tank with Flat Bottoms • Vertical Cylindrical Tank • Rectangular Tank with Flat Bottoms • Rectangular Tank with Sloping Sides |

| Temperature | • Temperature Conversion • Formation Temperature |

| Volume and Capacity | • Volume Conversion • Pipe Capacity • Pipe Displacement • Annular Capacity • Pipe and Annular Volumes • Hole ID from Hole Volume • Equivalent Hole ID from Caliper Volume • Equivalent Hole ID from Excess • Stroke |

| Well Control | • Maximum Surface Pressure and Pit Gain • Choke Line Pressure Loss • New Estimated Choke Line Pressure Loss • Formation Pressure and Kill Mud Weight • Gas Flow into the Wellbore • Height and Weight of Influx • Hydrostatic Pressure Reduction • Kick Severity • Kick Tolerance • Rate of Gas Migration in a Shut-in Well • Shut-in Casing Pressure • Shut-in Drillpipe Pressure • Bottom Hole Pressure with the Well Shut-In On A Kick • BHP When Circulating Out A Kick - Offshore • Maximum Mud Weight with Returns to Rig Floor • Casing Burst Pressure - Subsea Stack |

| Well Path | • True Vertical Depth • Build-and-hold: Finding Kop • Build-and-hold: Finding Build Rate • Build-and-hold: Finding Maximum Inclination • Build-and-drop: Finding Kop • Build-and-drop: Finding Maximum Inclination • Build-and-build: Finding Kop • Build-and-build: Finding Intermediate Inclination • Horizontal: Finding Kop • Horizontal: Finding Intermediate Inclination • Dogleg Severity • Survey and 3D Visualization |

| Wellbore Stability | • Mud Weight for Inclined Holes • Maximum Allowable Mud Weight from Lot |

| Wireline | • Wireline Diameter • Wireline Weight • Wireline Tension For One Section |

| Mud Formulation | • Mud Formulation |

Like what you are reading? You are welcome to download this white paper or read more of our white papers.

You may also be interested in: